U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

The best way to maintain sidewalks and other pedestrian facilities is to start by building them to last. Some common types of sidewalk damage can be prevented or slowed through the use of exceptional practices in initial sidewalk construction. In particular, close attention to specific design details can result in sidewalks that require low or lower levels of maintenance over their lifespan, thereby improving access in a community and reducing municipal and property owner costs. This chapter will highlight specific construction techniques that can lengthen the standard lifespan of pedestrian facilities.

Initial design and construction methods greatly influence the long-term maintenance and lifespan of sidewalks. Historically concrete has been the material of choice by many jurisdictions because of its ease of installation, durability, reliability and availability of materials. The thickness of the sidewalk material, use of reinforcing bars or mesh use of aggregate base, depth of sub-base below the sidewalk, distance from trees, and other design details impact how well a sidewalk will age over time. If best practices are followed, the expected sidewalk materials service life can be as long as:

Although the lifespans noted above are achievable, many cities consider 25 years to be an expected lifespan for concrete sidewalk. While some data exists on construction methods that can mitigate the potential for future damage, more research is needed on sidewalk construction best practices for reduced maintenance. There is an opportunity for increased research in this area.

As discussed in chapter 3, sidewalks and paths fail for a variety of reasons including damage due to:

Much of this damage can be avoided or delayed by using proper construction techniques that take into account the type of soils underlying the sidewalk, seasonal conditions that impact soils underlying sidewalks, tree type and placement and sidewalk design (thickness, use of aggregate, sub-drainage, and reinforcement).

The type of soil underlying a sidewalk may be the greatest determinant if the sidewalk will fail before the end of its projected lifespan. A comprehensive study in Cincinnati showed a greater correlation between sidewalk failure and the underlying soil type than between sidewalks and the presence of nearby trees. Providing an adequate subgrade below sidewalks may deter many of these failures by providing stability and good drainage, helping the sidewalk be more resistant to seasonal changes. Subgrade design and preparation should be carefully considered and based on local soil conditions and policies. Although there is not one specific design solution for every situation, Canadian national guidance27 provides the following general best practices:

Providing an adequate subgrade of free-draining material may also reduce problems from nearby tree roots, as detailed below.

Figure 34: Five inches of concrete sidewalk

Sidewalk thickness is just another aspect of the overall sidewalk "pavement" design, and should take into consideration expected loading, local soil conditions and policies. In the United States, concrete sidewalk thicknesses in warm climates that do not need to support heavy vehicles may be as low as 3.5 inches; areas that experience a winter freeze and must accommodate heavy vehicles (known as vehicle loading) may require thicknesses of 6 inches or more. In theory, the thicker the sidewalk, the less likely it will fail prematurely; however, adequate research does not exist to support this claim in the case of frost heave or tree roots. It is important to ensure that sidewalks are constructed with enough thickness to support expected vehicle loading which may include maintenance vehicles or more substantial loads at driveway crossings. In some cases reinforcement (usually with a welded wire mesh or re-bar) can be used to increase the loading capacity of sidewalks. Similar to subgrade design, there is not one specific design solution for every situation; however, the following provides general practices for sidewalk thickness. FHWA's Pedsafe Guide recommends a minimum of 4 inches for concrete slab depth.

Based on research conducted for this report, municipalities commonly follow these cited practices by requiring the following sidewalk thicknesses: 5 inches standard depth, 6 inches at driveways, 7 inches at commercial driveways. State DOTs require thicknesses of 4 or 5 inches for most sidewalk sections and 6 to 8 inches for sidewalk sections crossing driveways (consistent with the depth of the driveway aprons). Additional thickness may also need to be considered where off-tracking by trucks occurs on curb ramps.

Figure 35: Inadequate shoulders on a path

resulting in edge damage.

Asphalt is commonly used on paths and for shoulders used as pedestrian facilities. Asphalt thicknesses for shared use paths can be as low as two inches if laid on top of an adequate aggregate depth of4 inches and if only very light duty equipment will use the path. If laying asphalt without a base and an expectation that only medium duty trucks may use the facilities, 8 inches may be needed. According to a recent report by the Illinois Center for Transportation – Best Practices for Bicycle Trail Pavement Construction and Maintenance in Illinois, a minimum hot-mix asphalt thickness for paths that can support regular- heavy-duty trucks is 3 inches over a 4 inch aggregate. Depths for asphalt sidewalks are not very well documented, but at a minimum should be 2 inches with an adequate aggregate depth similar to the minimum depth of an asphalt path. It is also important for the paths to be at least 10 feet wide to support truck wheels at the edges. Larger maintenance vehicles – especially when the edge of the path cannot be seen very well by drivers – can cause significant edge damage if wheels ride at the edges.

Proper sidewalk drainage is important for maintenance purposes and to provide a safe and comfortable experience for users. It is important to provide a slight cross slope on sidewalks to ensure proper drainage and prevent pooling of water, especially in climates where ice can form. Accessibility requirements prescribe a maximum cross slope of two percent. This provides adequate drainage, but does not adversely impact access for people with disabilities.

Sidewalk immediately behind the curb should be considered for installation of a sub-drain system parallel to the curb to facilitate drainage away from the base and reduce frost heave in cold climates. Additionally, providing a subgrade of quick-draining material as noted above will help reduce frost heave in areas with soils that drain poorly.

Control and expansion joints should be provided in all concrete sidewalks and paths to minimize cracking and guide where cracking should occur. However, decorative jointing/scoring should be minimized to avoid jarring bumps for pedestrians using wheelchairs. Also, saw cutting control/contraction joints is recommended because it provides a smoother surface than troweling joints into the surface. Joints should be level and as narrow as possible. For interlocking pavers, the maximum variation in height should be 2 millimeters.30

Full depth expansion joints should be placed adjacent to existing rigid structures such as poles, walls, hydrants and buildings. Isolation joints should also be located at the beginning and end of curved sections of sidewalk and at all intersections.

Control joints, also known as contraction joints or construction joints, allow shrinkage to occur during drying in a way that does not affect the appearance of the sidewalk. It is generally recommended that control joints be spaced a maximum distance of 24 to 30 times the thickness of the concrete. The transverse contraction joint should extend to a depth of one quarter to one third of the depth of the concrete sidewalk and be a maximum width of 5 millimeters. If the sidewalk width is 2.5 meters (8 feet) or greater, a control joint should also be formed along the center line of the walk. It is recommended that the control joints be saw cut instead of trowelled.

Asphalt sidewalks typically do not need joints or scoring patterns.

Curb ramps and detectable warning surfaces present unique maintenance needs. The primary issues with detectable warning fields are debris collection, detachment from the sidewalk, or damage to the domes in the warning fields themselves. Detectable warning fields tend to collect dirt and debris between raised domes where pooling occurs during rain events. During the design, it is important to maintain a gutter slope that allows water entering the curb ramp to drain and carry away the debris. The primary solution to this issue is frequent sweeping. Seasonal pressure washing of detectable warning fields may also be of value, and may help retain the color contrast between the detectable warning field and the surrounding sidewalk.

Physical damage to detectable warning fields and their domes is common in areas that require snow removal. Detectable fields are easily damaged by snowplows that clear some paths and sidewalks, and can even be damaged by snowblowers. Extending the life of these fields can be accomplished by material selection. A few manufacturers are now providing cast iron detectable warning fields that are significantly heavier and stronger than those manufactured from stainless steel, alloy, concrete pavers, thermoplastic or pressed directly into the concrete. The cast iron detectable warning fields may be excessive for areas that do not experience significant snowfall, but may provide reduced maintenance and replacement costs in areas with snowfall.

Detectable warning surfaces pressed directly into fresh concrete are not recommended because they suffer from two problems. First, it is common for some of the concrete domes to be only partially formed during the initial installation on the curb ramp. When this occurs, it is likely that the incomplete domes will break off. Second, snow removal equipment, and even household snowblowers, can cause damage to concrete domes. If concrete detectable warning fields are used, a regular inspection schedule should be developed to monitor the integrity of the fields and perform necessary maintenance. In accordance with ADA Guidelines, domes that are pressed into concrete must be painted a contrasting color to aid those with visual disabilities. The contrasting paint rarely adheres to the domes for very long.

Street trees are important in enhancing the aesthetics of a corridor, providing shade and green space in urban environments and helping define the character of a corridor. The presence of mature street trees also increases the value of adjacent properties.31 However, street trees can also cause damage to sidewalks and walkways when either the trees or sidewalks are poorly sited. In many communities this is the primary cause of sidewalk damage and replacement. Proper site conditions, including soils, tree selection and location are all essential to ensure that the trees thrive in their location and do not interfere with nearby utilities, sidewalks or streets. Trees should typically be "limbed up" ensuring branches grow above and away from the sidewalk. Trees with drooping or low growing branches can create hazards for nearby pedestrians or vehicles.

The following guidance on street trees is impacted by urban design standards, such as planting strip widths, right-of-way widths, sidewalk widths and even the presence of curb and gutter. Along with the following guidance focused directly on street trees, agencies need to address deficiencies in their urban design standards that can help promote better street designs for trees and sidewalk preservation. At the national level, the AASHTO Guide for Planning, Design, and Operation of Pedestrian Facilities has some guidance as well as ITE's Designing Walkable Urban Thoroughfares: A Context Sensitive Approach. Many state agencies will also have street design handbooks that can provide guidance on urban design standards.

One of the best ways to support healthy street trees and protect against sidewalk damage is provision, selection and management of proper soils. Often trees in the right-of-way are planted in existing soils compacted to support motor vehicles. Roots in compacted soil will migrate toward the surface for air and water, causing sidewalk to crack and heave. These soils can ultimately lead to damage of underground utilities, sidewalks and roadways. To abate costly maintenance issues it is important to consider the relationship between soils, street trees and sidewalks. Important factors to consider include the amount of soil provided (discussed later in the chapter), the soil content and the maintenance of soils over time:

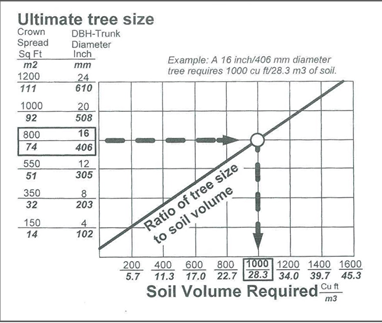

Street trees need adequate space to grow to maturity. Tree roots do not survive in confined space and compacted soils so it is important to maximize soil volume appropriate to street tree species. In the confined street right-of-way this is often challenging and expensive but provision of appropriate soil volume enables the tree to grow a mature, healthy canopy and lessens the chance that roots will damage underground utilities or the adjacent sidewalk. Published research suggests that increasing soil volumes is one of the best ways to enable larger and healthier trees in cities. Soil volume recommendations range from a minimum of 400 cubic feet to more than 1000 cubic feet based on the sidewalk width.33 One of the first steps is to simply determine the soil volume requirements per tree volume. Volume will vary depending on climate, soil type and desired tree species. The following diagram provides some general guidance.

Figure 36: Tree size to soil volume relationship. Urban,

Table 2.4.1, page 205, 2008.

A variety of innovations in engineered soils to support root growth have been developed primarily for streets in urban and suburban locations with curb and gutter where plantings are desired in spatially constrained conditions. These strategies adopted from Up By Roots by Jim Urban34 are intended to increase the volume of rooting soil while maintaining accessible sidewalks:

Tree pits are used where space or resources do not permit the use of open or covered tree trenches. This option is less desirable for new construction than the techniques described above because it often does not allow for adequate soil volume. However, tree pits are often an existing condition that can be improved with the addition of amended soils. For new construction, tree pits should be as large as possible to provide maximum rooting volume while maintaining appropriate clear width for sidewalks. The sides of the pit below the sidewalk should be open to the surrounding subgrade to allow for root penetration and drainage beyond the pit. Tree pits are often covered by grates to minimize soil compaction and trip hazards, but the grates require maintenance to adjust for tree growth and to correct for settlement that may cause a tripping hazard. Open tree pits, and in some cases covering them with tree grates, are acceptable treatments with proper maintenance.

Figure 37: Modular plastic pavers near a tree.

The preferred size for a tree pit is at least 4 feet by 10 feet by 3 feet deep for 120 cubic feet. According to published research, trees need 1 to 2 cubic feet of soil volume for every square foot of crown area spread. Smaller tree pits, as narrow as 2'-6" wide, may be appropriate if sidewalk constraints prohibit the construction of a full size tree pit and sufficient soil volume is provided. However, tree pits are often the cause of sidewalk damage; trees can outgrow the pit and buckle the sidewalk. Solutions to small existing tree pits include using high-nutrient amended soils, installing permeable pavers around the tree pit, expanding the opening of the tree pit or introducing mulch. Rubber sidewalks can also alleviate sidewalk buckling adjacent to tree pits. Modular rubber sidewalks and flexible porous pavements allow for root growth while reducing tripping hazards by providing a rounded rather than buckled surface.

Planting street trees in appropriate sites will help promote their successful growth and development while minimizing sidewalk and street maintenance issues commonly caused by poorly sited trees. Following are broad guidelines drawn primarily from Chapter 11 of the Los Angeles County Model Design Manual for Living Streets35:

Where space is limited between the curb and the sidewalk consider planting street trees on private property adjacent to a sidewalk. Doing so can increase the tree setback from the sidewalk, reduce the likelihood of root damage, and give roots more room to grow.

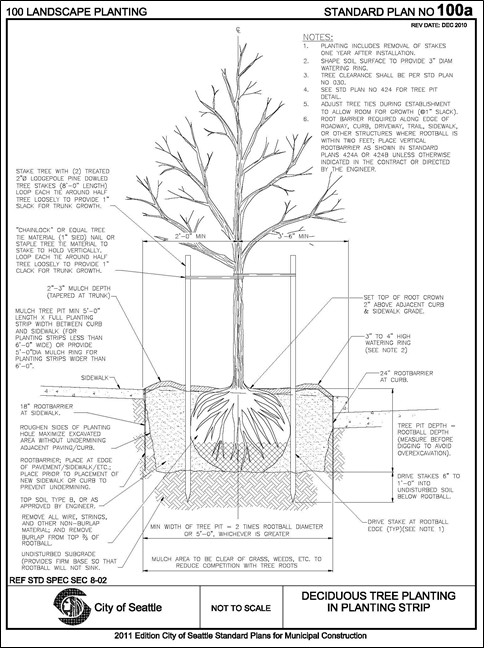

Figure 38: Standard specification for street tree planting. Seattle Department of Transportation, 2011.

Street trees should be carefully selected to ensure that they will be compatible with their surroundings and will minimize the potential of future damage to sidewalks. Since appropriate trees will vary from location to location, work with an arborist horticulture specialist, landscape architect or other qualified professional to help assess the site and conditions that apply to the selection of proper tree species. Below are some points for identifying desirable features:

Figure 39: Partial list of approved street trees. Seattle Department of Transportation.

27 Sidewalk Design, Construction, and Maintenance: A Best Practice by the National Guide to Sustainable Municipal Infrastructure. Federation of Canadian Municipalities and National Research Council.

28 Ibid.

29 Ibid.

30 Sidewalk Design, Construction, and Maintenance: A Best Practice by the National Guide to Sustainable Municipal Infrastructure. Federation of Canadian Municipalities and National Research Council. July 2004.

31 Wolf, Kathleen, City Trees and Property Values, Arborist News (August 2007), PP. 34-36

33 Casey Trees, Tree Space Design, 2008,PP. 3

34 Urban, Jim, Up By Roots: Healthy Soils and Trees in the Built Environment. International Society of Arboriculture, Champaign, IL. 2008.

35 Bogart, S; Snyder R. et al. The Los Angeles County Model Design Manual for Living Streets , Los Angeles County, 2011. http://www.modelstreetdesignmanual.com