U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

![]()

U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Ave. S.E.

Washington, D.C. 20590

July 29, 2013

In Reply Refer To:

HSST/B-39C

Ms. Maggie Ellis

General Manager

Mondo Polymer Technologies

27620 State Route 7

P.O. Box 250

Reno, Ohio 45773

Dear Ms. Ellis:

This letter is in response to your request for the Federal Highway Administration (FHWA) to review a roadside safety system for eligibility for reimbursement under the Federal-aid highway program.

| Name of system: | Mondo Polymer Blockout for Midwest Guardrail System (MGS) |

|---|---|

| Type of system: | Strong Steel Post W-beam guardrail |

| Test Level: | MASH Test Level 3 |

| Testing conducted by: | Midwest Roadside Safety Facility |

| Task Force 13 Designator: | PPB02 |

| Date of request: | June 4, 2013 |

Decision:

The following device is eligible, with details provided in the form which is attached as an integral part of this letter:

Based on a review of "bogie vehicle" component crash test results submitted by the manufacturer certifying the device described herein meets the crash test and evaluation criteria of the American Association of State Highway and Transportation Officials' Manual for Assessing

Safety Hardware (MASH), the device is eligible for reimbursement under the Federal-aid highway program. Eligibility for reimbursement under the Federal-aid highway program does not establish approval or endorsement by the FHWA for any particular purpose or use.

The FHWA, the Department of Transportation, and the United States Government do not endorse products or services and the issuance of a reimbursement eligibility letter is not an endorsement of any product or service.

Requirements

To be found eligible for Federal-aid funding, roadside safety devices should meet the crash test and evaluation criteria contained in the American Association of State Highway and Transportation Officials' Manual for Assessing Safety Hardware (MASH).

Description

The device and supporting documentation are described in the attached form.

Summary and Standard Provisions

Therefore, the system described and detailed in the attached form is eligible for reimbursement and may be installed under the range of conditions tested.

Please note the following standard provisions that apply to FHWA eligibility letters:

Sincerely yours, /* Signature of Michael S. Griffith */ Michael S. Griffith |

Enclosures

| Submitter | Date of Request: | June 04, 2013 | |

| Name: | Maggie Ellis | Signature: /s/ Maggie Ellis | |

| Company: | Mondo Polymer Technologies, Inc. | ||

| Address: | P.O. Box 250 Reno, OH 45773 | ||

| Country: | United States of America | ||

| To: | Michael S. Griffith, Director FHWA, Office of Safety Technologies |

||

I request the following devices be considered eligible for reimbursement under the Federal-aid highway program.

| System Type | Submission Type | Device Name/Variant | Testing Criterion | Test Level |

|---|---|---|---|---|

| 'B': Barriers (Roadside, Median, Bridge Railings) | Mondo Polymer Blackout for Midwest Guardrail System |

AASHTO MASH | TL3 |

By submitting this request for review and evaluation by the Federal Highway Administration, I certify that the product(s) was (were) tested in conformity with the AASHTO Manual for Assessing Safety Hardware and that the evaluation results meet the appropriate evaluation criteria in the MASH.

Identification of the individual or organization responsible for the product:

| Contact Name: | Maggie Ellis | Same as Submitter ☒ |

| Company Name: | Mondo Polymer Technologies, Inc. | Same as Submitter ☒ |

| Address: | P.O. Box 250 Reno, OH 45773 | Same as Submitter ☒ |

| Country: | United States of America | Same as Submitter ☒ |

| |

Non-Significant – Effect is positive or Inconsequential | |

|---|---|---|

|

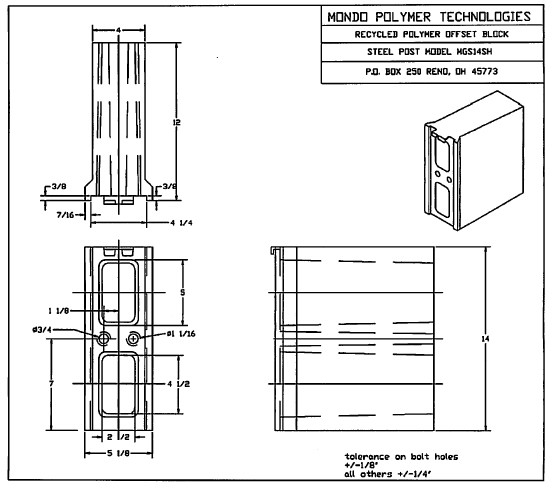

The Midwest Guardrail System (MGS) utilizes 6 ft. long, W6x9 steel guardrail posts with 12 inch deep, southern yellow pine wood blackouts. The MGS has previously met the safety performance criteria set forth in the AASHTO "Manual for Assessing Safety Hardware (MASH) [1) Test Level (TL-3) safety performance criteria [2-4]. The Mondo Polymer composite blackout is an alternative choice to be used in conjunction with the MGS. The dimensions of the Mondo Polymer blackout are 356 mm long by 102 mm wide at the block/guardrail interface and remain constant for 263 mm before Oaring out to 130 mm at the post/block interface. A 10 mm deep by 108 mm wide recess accommodates the post flange, making the effective block depth 295 mm. In addition, the block has two rectangular openings that taper from 64 mm by 114 mm at the guardrail/block interface to 76 mm by 127 mm at the post/block interface. There are two bolt holes that are 19 mm at the guardrail/block interface and 27 mm at the post/block interface. The Mondo Polymer MGS Composite blackout is manufactured from approximately 95% recycled Polyethylene and 5% trace materials and weighs approximately 10 lbs. |

||

A brief description of each crash test and its result:

| Required Test Number | Narrative Description | Evaluation Results |

|---|---|---|

| 3-10 (1100C) | On February 5, 2013, University of Nebraska Midwest Roadside Safety Facility conducted two dynamic component tests in lieu of full scale crash tests. MwRSF Research Report No. TRP-03-289-13 included the setup of both Mondo Polymer Tech., plastic blackout (Test no. MOND0-1) and a standard, 12-in. SYP wood blackout (Test no. MOND0-2) both on a standard W6x8.5 (W152x12.6) steel posts. Both tests were conducted with a bogie vehicle impacting at target impact conditions of a speed of 20 mph (32.2 km/h) and an angle of 0 degrees, creating a classic "head-on" or full frontal impact and strong axis bending. Based on the results of the two crash tests, no significant differences were observed between the performance of the wood and plastic spacer blocks. Both blocks displayed similar levels of permanent damage after impact. Analysis showed that the plastic block remained firmly attached to the post during the impact event. No concerns were observed with regards to the dynamic performance or the structural integrity of the plastic blackout when compared with the wood blackout. |

WAIVER REQUEST |

| 3-11 (2270P) | On February 5, 2013, University of Nebraska Midwest Roadside Safety Facility conducted two dynamic component tests in lieu of full scale crash tests. MwRSF Research Report No. TRP-03-289-13 included the setup of both Mondo Polymer Tech., plastic blackout (Test no. MOND0-1) and a standard, 12-in. SYP wood blackout (Test no. MOND0-2) both on a standard W6x8.5 (W152x12.6) steel posts. Both tests were conducted with a bogie vehicle impacting at target impact conditions of a speed of 20 mph (32.2 km/h) and an angle of 0 degrees, creating a classic head-on" or full frontal impact and strong axis bending. Based on the results of the two crash tests, no significant differences were observed between the performance of the wood and plastic spacer blocks. Both blocks displayed similar levels of permanent damage after impact. Analysis showed that the plastic block remained firmly attached to the post during the impact event. No concerns were observed with regards to the dynamic performance or the structural integrity of the plastic blackout when compared with the wood blackout. |

WAIVER REQUEST |

| 3-20 (1100C) | Not applicable | |

| 3-21 (2270P) | Not applicable |

Full Scale Crash Testing was done in compliance with MASH by the following accredited crash test laboratory (cite the laboratory's accreditation status as noted in the crash test reports.):

| Laboratory Name: | Midwest Roadside Safety Facility | |

| Laboratory Contact: | Karla Lechtenberg, M.S.M.E., E.I.T. | Same as Submitter ☐ |

| Address: | Nebraska Transportation Center University of Nebraska-Lincoln 130 Whittier Research Center 220 Vine Street Lincoln, Nebraska 68583-0853 |

Same as Submitter ☐ |

| Country: | United States | Same as Submitter ☐ |

| Accreditation Certificate Number and Date: |

2937.01 | |

Attach to this form:

FHWA Official Business Only:

| Eligibility Letter | AASHTO TF13 | Key Words | |

|---|---|---|---|

| Number | Date | Designator | |

| B-39C | July 8, 2013 | PPB02 | Blockout, Offset Block, MGS, Midwest Guardrail |