Federal Highway Administration |

400 Seventh St., S.W. |

June 14, 2007

In Reply Refer To: HSSD/CC-99

Mr. Michael Kempen

Impact Absorption

46-04 245th Street

Douglaston, NY 11362

Dear Mr. Kempen :

Thank you for your mail correspondence requesting the Federal Highway Administration’s (FHWA) acceptance of the U-MÄD Trailer Mounted Attenuator for use on the National Highway System (NHS) under the provisions of the National Cooperative Highway Research Program (NCHRP) Report 350 "Recommended Procedures for the Safety Performance Evaluation of Highway Features". Accompanying your letter was a report on testing of your company's Trailer Mounted Attenuator conducted by the Transportation Research Center Inc. and test videos. You also enclosed drawings of the device and some copies of relevant FHWA acceptance letters. The energy absorbing system (U-MÄD 100K) used in the Trailer Mounted Attenuator was accepted before when directly attached to the support vehicle (acceptance letters HSA-10/CC64, HSA-10/CC64A and HSA-10/CC64D). Also, the trailer used with the Trailer Mounted Attenuator was previously accepted when used with another type of previously approved energy absorbing system, Vanderbilt Truck-Mounted Attenuator (TMA) (acceptance letter HSA-10/CC-36D). This letter provides a provisional acceptance of the U-MÄD Trailer Mounted Attenuator.

Requirements

Truck-mounted attenuators should meet the guidelines contained in the NCHRP Report 350, "Recommended Procedures for the Safety Performance Evaluation of Highway Features". FHWA Memorandum “ACTION: Identifying Acceptable Highway Safety Features” of

July 25, 1997 provides further guidance on crash testing of TMAs.

Product description

The U-MÄD 100K TMA is constructed from an aluminum box, having an outer shell thickness of 0.050 in. (1.27mm) and structural supporting elements. Within the shell is a cushion constructed into eight compartments, each compartment containing variable cellular velocity dissipating material of varying density (CVDM) which is a honey combed, cellulose based material. All seams are welded and steel riveted and both internally and externally sealed to prevent moisture intrusion. Additionally, each unit of crushable CVDM is contained in its own separate moisture barrier.

The U-MÄD 100K TMA assembly is mounted to a two-wheel trailer which is connected to the rear of the support truck by means of a hitch. Overall length of the U-MÄD 100K TMA is 130 in (3.3 m). Weight of the U-MÄD 100K TMA is 930 lb (421 kg), trailer weight is 1310 lb (597 kg). Details of the U-MÄD 100K TMA are shown in Enclosure 1.

Testing – Discussion

The NCHRP Report 350 requires that in order for the truck-mounted attenuators to be accepted as the NCHRP Report 350 devices they must successfully pass Tests 3-50 and 3-51 while Tests S3-50, 3-52 and 3-53 are optional. However, since your company’s Trailer Mounted Attenuator incorporates the energy absorbing system (U-MÄD 100K) already accepted before (when directly attached to the support vehicle) and the trailer previously accepted (when used with another type of energy absorbing system), you conducted only one optional Test (3-52) instead of running both Tests 3-50 and 3-51, assuming that this test will be more critical.

As you indicated in your request, in previous discussions with Mr. Powers of my staff it was agreed that the worst case scenario for a Trailer Mounted Attenuator was the potential for the impacting vehicle to merely push the Trailer Mounted System away from the back of the support vehicle thereby exposing the impacting vehicle and driver to a lethal impact with the rear section of the shadow vehicle. This concern required that Test 3-52 be completed on any Trailer Mounted System for a NCHRP 350 acceptance when that system, as a Truck Mounted Attenuator, had been tested and accepted previously to NCHRP 350. At that time it was concluded that the NCHRP Report 350 Test 3-52 would suffice to test your company’s Trailer Mounted Attenuator for use on the NHS under the provisions of the NCHRP Report 350 and Tests 3-50 and 3-51 would be waived.

Since then, another recent TMA to Trailer conversion showed unacceptable performance when subjected to Test 3-51 after passing both Test 3-52 and Test 3-53. This led us to reconsider our understanding that the Test 3-52 alone was a satisfactory measure of TMA to Trailer conversions. An independent engineering evaluation of the system in question concluded:

“It appears that some features inherent to trailer-mounted devices (such as non-rigid attachment to the host truck, anti-rotating systems …) in combination might change the performance of the device compared to its original truck-mounted design. Especially, additional degree of freedom (vertical rotation at the hook assembly) appears to be a factor which can lead to differences in performance. With this new knowledge, we maintain that it is important to verify the performance … in the NCHRP 350 test 3-51.

In the case of the UMAD-100K TMA Trailer, the supporting wheels are located adjacent to the front of the unit, which is the same location as the successfully tested TMA. However, the non-rigid attachment and the use of the anti-rotating system are two of the factors that have an unknown effect on the system’s performance. We will therefore require that the U-MÄD be tested with NCHRP Report 350 Test 3-51 within 90 days of the date of this letter.

Test 3-52

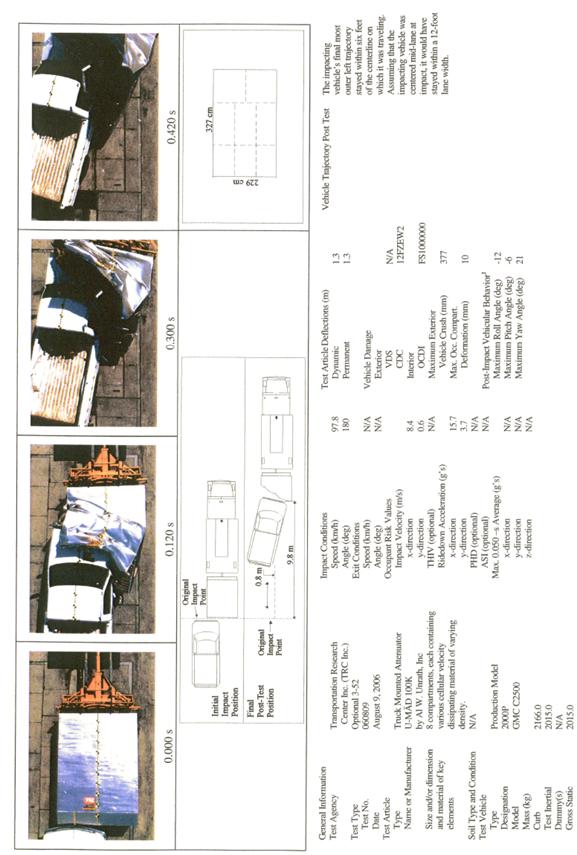

The full-scale NCHRP Report 350 Test 3-52 conducted on your company’s Trailer Mounted Attenuator involved a 2000P vehicle impacting the device at 97.8 km/h and at a 0 degree angle with the centerline of the vehicle offset 782 mm leftward from the centerline of the U-MÄD 100K. The weight of support truck was 19260 lb (8755) kg. The impacting vehicle came to rest 9.8 meters from the impact point and 0.8 meters to the left at an approximate lateral angle of

21 degrees clockwise from its original line of travel. The support vehicle came to rest approximately 7.2 meters forward with its right rear corner, 0.6 meters to the right of its initial position.

All occupant risk factors were within the limits specified in NCHRP Report 350. For the impacting vehicle, in the longitudinal direction, the occupant impact velocity was 8.4 m/s and the highest 0.010-s occupant ridedown acceleration was 15.7 g. In the lateral direction, the occupant impact velocity was 0.6 m/s and the highest 0.010-s occupant ridedown acceleration was 3.7 g.

For the support vehicle, in the longitudinal direction, the occupant impact velocity was 4.1 m/s and the highest 0.010-s occupant ridedown acceleration was 1.1g. In the lateral direction, the occupant impact velocity was 0.4 m/s and the highest 0.010-s occupant ridedown acceleration was 1.1 g. Both the impacting and support vehicles remained upright and stable and the impacting vehicle was brought to a controlled stop. Summary of test results are provided in Enclosure 2.

The U-MÄD 100K was extensively damaged, with the most severe damage occurring front to back on the left two thirds, when looking at the rear in a forward direction. Most of the damage to the impacting vehicle was to the right front corner. Maximum crush into the occupant compartment of the impacting vehicle was 0.39 in (10 mm) at the right window lower edge to left window upper edge reference point area.

FHWA Acceptance

In summary, I agree that Trailer Mounted Attenuator as described above, meets the appropriate evaluation criteria for the NCHRP 350 Test 3-52 and may be used at all appropriate locations on the NHS when selected by the contracting authority, subject to the provisions of Title 23, Code of Federal Regulations, Section 635.411 as they pertain to proprietary products. This acceptance is based on the testing agreed to by Mr. Powers. As we have now concluded that Test 3-51 is also a critical test for TMA to Trailer conversions, our acceptance is provisional at this time. You will have 90 days to have NCHRP Report 350 test 3-51 conducted. If successful, we will remove this restriction and reissue this letter as a permanent acceptance.

Standard provisions

Please note the following standard provisions that apply to FHWA letters of acceptance:

|

Sincerely yours,

George (Ed) Rice, Jr. |

Title 23, Code of Federal Regulations

§ 635.411 Material or product selection.

(a) Federal funds shall not participate, directly or indirectly, in payment for any premium or royalty on any patented or proprietary material, specification, or process specifically set forth in the plans and specifications for a project, unless:

(1) Such patented or proprietary item is purchased or obtained through competitive bidding with equally suitable unpatented items; or

(2) The State transportation department certifies either that such patented or proprietary item is essential for synchronization with existing highway facilities, or that no equally suitable alternate exists; or

(3) Such patented or proprietary item is used for research or for a distinctive type of construction on relatively short sections of road for experimental purposes.

(b) When there is available for purchase more than one nonpatented, nonproprietary material, semifinished or finished article or product that will fulfill the requirements for an item of work of a project and these available materials or products are judged to be of satisfactory quality and equally acceptable on the basis of engineering analysis and the anticipated prices for the related item(s) of work are estimated to be approximately the same, the PS&E for the project shall either contain or include by reference the specifications for each such material or product that is considered acceptable for incorporation in the work. If the State transportation department wishes to substitute some other acceptable material or product for the material or product designated by the successful bidder or bid as the lowest alternate, and such substitution results in an increase in costs, there will not be Federal-aid participation in any increase in costs.

(c) A State transportation department may require a specific material or product when there are other acceptable materials and products, when such specific choice is approved by the Division Administrator as being in the public interest. When the Division Administrator's approval is not obtained, the item will be nonparticipating unless bidding procedures are used that establish the unit price of each acceptable alternative. In this case Federal-aid participation will be based on the lowest price so established.

(d) Appendix A sets forth the FHWA requirements regarding (1) the specification of alternative types of culvert pipes, and (2) the number and types of such alternatives which must be set forth in the specifications for various types of drainage installations.

(e) Reference in specifications and on plans to single trade name materials will not be approved on Federal-aid contracts.

(f) In the case of a design-build project, the following requirements apply: Federal funds shall not participate, directly or indirectly, in payment for any premium or royalty on any patented or proprietary material, specification, or process specifically set forth in the Request for Proposals document unless the conditions of paragraph (a) of this section are applicable.

[41 FR 36204, Aug. 27, 1976, as amended at 67 FR 75926, Dec. 10, 2002]