U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

An important aspect of reducing the number of CMV-involved crashes is providing areas for drivers to rest and enforcing regulations designed to ensure CMVs and their drivers are in good condition. Safety infrastructure improvements can assist with making these operations more feasible. This chapter discusses these practices along with practices attempting to provide some separation of large vehicles from the more agile stream of passenger vehicles.

The primary mission of FMCSA is to reduce crashes, injuries, and fatalities involving large trucks and buses. The FMCSA enforces Federal motor carrier safety regulations primarily through the Motor Carrier Safety Assistance Program (MCSAP). The roadside inspection portion of the MCSAP consists of roadside inspections performed by qualified State and local safety inspectors, following guidelines developed by FMCSA and the Commercial Vehicle Safety Alliance. Six levels of inspections include a vehicle component, a driver component, or both. Separately, the traffic enforcement component of MCSAP is composed of two distinct activities: a traffic stop as a result of a moving violation and a subsequent roadside inspection. Infrastructure improvements to provide wider shoulders or specifically designed pullout areas, where roadside inspections can be conducted with less risk of drivers in the adjacent travel lanes intruding into the inspection space, would be beneficial to these important safety activities.

The FMCSA has developed the Roadside Intervention Effectiveness Model to estimate the effects of these safety enforcement programs. The model associates each violation of the Federal Motor Carrier Safety Regulations with a specific crash probability. Using these probabilities, analysts can estimate the number of crashes prevented as a result of correcting these violations. The model estimates that for roadside inspection and traffic enforcement in 2012, these programs saved 472 lives and prevented 8,833 injuries by averting more than 14,424 crashes.(68) The following safety practices are associated with roadside equipment that aids in inspection and enforcement activities or countermeasures that aid in rules compliance.

Like the Federal Railroad Administration for train crews and the Federal Aviation Administration for pilots, FMCSA enforces hours of service regulations for CMV drivers, establishing rest periods, breaks, and the maximum number of hours over a certain period.(69) In order for drivers to comply with the mandatory rest rules, drivers need to find safe, available parking.(70) The challenges of finding available parking can mean that drivers spend more time on the road hunting for parking when they should be resting.

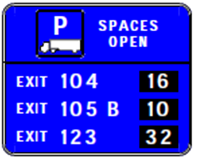

To address this problem, States are using FMCSA and DOT grant programs to implement intelligent transportation systems that monitor truck parking spaces in public rest areas and some private truck stops. These smart systems communicate space availability to CMV drivers either directly through phone messages or via roadside message signs (Figure 24 and Figure 25).(71,72) A variety of technologies are being deployed to monitor space occupancy and availability, but the common element is providing drivers with reliable, timely information. This information should reduce time spent hunting for parking and reduce the safety risks to drivers that park in less safe locations. These intelligent transportation system parking systems can also be accompanied or leveraged by truck parking expansions in public rest areas in order to reduce the number of trucks that park overnight in unsafe areas.

Source: Photo Courtesy HNTB Corporation.(73)

Figure 24

Photo. SmartPark in Michigan.

Source: FHWA

Figure 25. Graphic. Current recommended sign design.

Cost-Effectiveness Assessment: Truck parking systems are assessed as tried and high cost.

A number of States have tested infrared screening technology in roadside detection devices that identify overheated and inoperable brakes. The testing also involved screening for additional safety inspections and subsequent checks of credentials and safety compliance. Such screening can help remove unsafe vehicles and drivers from the roadway, gaining safety benefits by preventing crashes caused by malfunctioning or inadequate brakes. In some cases, these detection devices can catch brake problems before the driver is aware of them.

Cost-Effectiveness Assessment: Infrared braking detection systems are assessed as experimental/promising and moderate to high cost.

Electronic screening is a process deployed in advance of State roadside safety inspection facilities that electronically identifies a CMV; verifies its size, weight, and credentials information; and reviews its carrier's past safety performance, all while the vehicle is in motion. The driver receives in-cab signals to pull into the inspection or weigh station or bypass it based on the screening results. Vehicles that are properly credentialed, operated by a motor carrier with a history of safe operations, and within weight are allowed to bypass inspection facilities. Not all sites are instrumented for weight measurements, and random inspections may still be performed for those meeting all the listed criteria.

Electronic screening projects are designed to target roadside enforcement services aimed at high-risk motor carriers or vehicles and to reduce operating costs for safe and legal motor carriers. Fixed, virtual, or mobile inspection stations that can provide this functionality are examples of electronic screening implementations. Transponders or other onboard wireless mobile data devices that transmit and receive information between the driver and the inspection site can be used to fulfill the e-screening requirement for Core Compliance with FMCSA's Innovative Technology Deployment program.

Cost-Effectiveness Assessment: Electronic screening is assessed as proven and moderate to high cost.

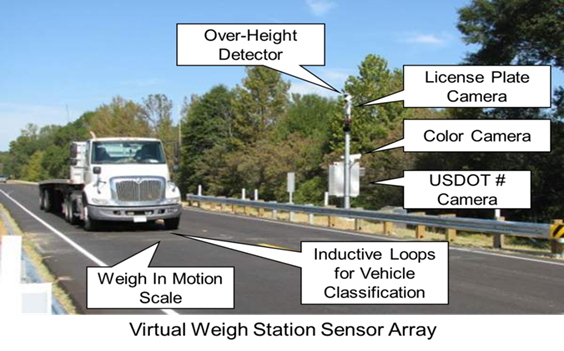

Unstaffed and remotely monitored roadside enforcement facilities, commonly called virtual weigh stations (shown in Figure 26), are deployed to address some of the limitations in States' traditional roadside enforcement programs.(74) These facilities can screen CMVs on routes that bypass fixed inspection stations, on secondary roadways, and in heavily populated urban or geographically remote locations where it may be difficult to deploy traditional enforcement operations. Data from virtual weigh station sites can effectively target enforcement resources on roadways where overweight trucks and noncompliant carriers are known or suspected to operate. Most States already use weigh-in-motion equipment for FHWA data collection requirements as part of the vehicle classification for Highway Performance Management System sampling.

Cost-Effectiveness Assessment: Virtual weigh stations are assessed as proven and moderate cost.

Source: FHWA.

Figure 26

Photo. Virtual weigh station.

The frequency of auto-truck interactions on a roadway can increase the aggregate safety risks of possible multivehicle crashes. States are experimenting with the use of regulatory measures to separate truck movements from the rest of traffic.

Some common problems associated with OS/OW vehicle movements, such as restrictive clearances, pavement condition, and vehicle interaction, may be managed through designating certain corridors with high freight volumes as OS/OW corridors through regulatory authority and infrastructure improvements.(75) Some States are experimenting with this around ports, but it is advocated for economic development purposes more than safety. The OS/OW movements in these corridors could be authorized through trip permits or regulatory changes to allow certain vehicle-weight combinations access to the corridor. These corridors could be designed and constructed specifically for OS/OW movements, using strategies such as limiting geometric changes along the road and payment of fees commensurate with the relative adverse effects on pavements and structures.

Cost-Effectiveness Assessment: OS/OW corridors are assessed as experimental/promising and high cost.

States have established truck lane restrictions to separate slow-moving trucks from faster-moving vehicles. This treatment includes the restriction of trucks from at least one lane (Figure 27). Studies suggest that restricting trucks to fewer lanes in general improves traffic operations and decreases pavement deterioration in the restricted lanes, while other studies show an improvement in safety.(36,76,77) A recent safety evaluation of truck lane restrictions found a 40 percent reduction in truck-related fatal and injury crashes on multilane freeways with traffic volumes below 10,000 vehicles per day, and a 14 percent increase for multilane freeways above that threshold.(77) Commercial operators may perceive this as a negative treatment since restricting trucks to fewer lanes limits their maneuverability. These lane restrictions are imposed as a regulatory measure, limiting truck movement in all lanes and posting associated signage to inform drivers.

Source: Texas A&M

Transportation Institute

Figure 27

Graphic. Truck lane restriction in Texas.

Cost-Effectiveness Assessment: Truck lane restrictions are assessed as proven and low cost.

| << Previous | Table of Contents | Next >> |