U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Ave. S.E.

Washington, D.C. 20590

July 11, 2008

In Reply Refer To: HSSD/B-179

Mr. Barry D. Stephens, P.E.

Sr. Vice President Engineering

Energy Absorption Systems, Inc.

3617 Cincinnati Avenue

Rocklin, CA 95678

Dear Mr. Stephens,

This letter is in response to your request for Federal Highway Administration (FHWA) acceptance of a roadside safety system for use on the National Highway System (NHS).

You requested that we find this system acceptable for use on the NHS under the provisions of National Cooperative Highway Research Program Report 350 “Recommended Procedures for the Safety Performance Evaluation of Highway Features.”

Requirements

Roadside safety systems should meet the guidelines contained in the NCHRP Report 350, "Recommended Procedures for the Safety Performance Evaluation of Highway Features". FHWA Memorandum “ACTION: Identifying Acceptable Highway Safety Features” of July 25, 1997 provides further guidance on crash testing requirements of longitudinal barriers.

Description

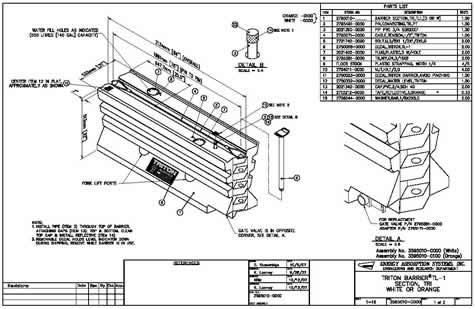

The new system is a portable, water-filled plastic longitudinal barrier intended for use as a temporary barrier in highway construction zones. Energy developed the TRITON BARRIER® TL-1 to prevent vehicle penetration at impact speeds up to 50 km/h (31 mph) and impact angles up to 25 degrees.

The test installation was 29.7 m (97.45 feet) long, consisting of 15 TRITON units. The dimensions of the individual Triton units are as follows:

| Height - | 813 mm (32 in) |

|---|---|

| Width - | 533 mm (21 in) |

| Length* - | 1981 mm (78 in) [*Length measured pin to pin] |

| Weight (empty) - | 45 kg (99 lbs) |

| Weight (full) - | 595 kg (1312 lbs) |

| Water ballast - | 550 L (145 gal) |

| Color(s) - | Orange and White |

The TRITON BARRIERÒ TL-1 barrier consists of multiple barrier sections pinned together using a 48 mm (1-½ in Schedule 40) diameter steel pipe connecting pin to optimize impacting vehicle redirection. Each individual section will incorporate a 12.7 mm (1/2 in) diameter steel cable towards the top of the unit to maximize the tension capacity of the system during impacts. The plastic mold design allows for the stacking of the empty sections (up to three high) during storage and transport. The TRITON BARRIERÒ TL-1 sections are identical to the TRITON BARRIERÒ TL-2 unit previously accepted by the FHWA except the internal steel framework inherent to these existing units was removed for this TRITON BARRIERÒ TL-1 test. A decal will be affixed to the exterior of each TRITON BARRIERÒ TL-1 section to prevent these units from being mistakenly being used with the TRITON BARRIERÒ TL-2 and the TRITON BARRIERÒ TL-3 products.

Crash Testing

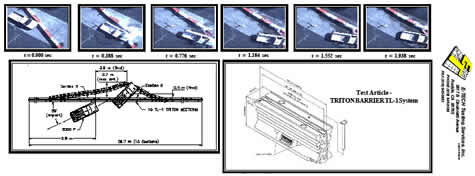

Full-scale crash testing was conducted on the TL-1 barrier. We concur that conducting one full-scale “capacity” NCHRP 350 test was adequate to validate the performance of this system. The test you completed was NCHRP 350 Test 1-11 (2000P/50KPH/25 deg). Your test verified that the impact performance for heavier vehicles (2000kg) was acceptable and successfully prevented vehicle penetration into the work zone behind the product. We noted that the nearly 30-meter (100-ft) long system was not anchored during the test, resulting in lateral barrier deflection of 2.7 meters (8.9 ft).

The test data sheet summarizing the results of the impact is enclosed for reference. Based upon the successful completion of the aforementioned NCHRP 350 test you provided, we agree that your TRITON BARRIER® TL-1 system is acceptable for use as a TL-1 longitudinal barrier. The system, as described above, may be used on the NHS when such use is acceptable to the contracting authority.

Findings

Therefore, the system described above and detailed in the enclosed drawing is acceptable for use on the NHS under the range of conditions tested, when acceptable to a highway agency.

Please note the following standard provisions that apply to FHWA letters of acceptance:

Sincerely yours,

David A. Nicol, P.E. |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Figure 1. Summary of Results - TRITON BARRIER TL-1 Test -1-4318-001