U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

| < Previous | Table of Contents | Next > |

There are four treatments that involve physical changes to the roadway and are relatively minor in costs; they are discussed in this chapter.

Description

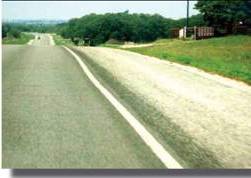

Replace unstable or narrow shoulders with paved shoulders to increase usable width and driver safety. Variations in surface color also provide a beneficial safety effect.

Application Guidelines

While tight budgets may influence an agency’s decision to upgrade to paved shoulders on two-lane tangent sections, the resulting cost benefit from paved shoulders and fewer crashes on curves deserves consideration.

Design

Reconstructing shoulders involve removing and recompacting a 6-in shoulder base. Agencies paving with asphalt can texturize the surface to provide visual, audible, and tactile clues to a driver leaving the travel lane. To texture the surface, apply a larger, uncoated seal coat on the shoulder while using a smaller aggregate seal coat on the driving lanes.

In addition to paving the shoulder, color variation between the shoulder and travel lanes adds visual delineation.

Effectiveness

Texas DOT (TxDOT) considers application of this treatment as operationally effective because of the visual, audible, and tactile cues that alert a driver straying onto the shoulder. TxDOT believes the treatment reduced the number of single-vehicle ROR crashes. The agency also reports a positive public response to the strong visual effect, which it regards as useful for nighttime travel.

Cost

The approximate cost of seal-coating a gravel shoulder is $1.00/yd2 (when not resurfacing the roadway).

Agency Contacts and Further Information

TxDOT applied the treatment cited above in Cook County. The TxDOT Fort Worth District Engineer is Maribel Chavez, P.E. (817-370-6500).

Description

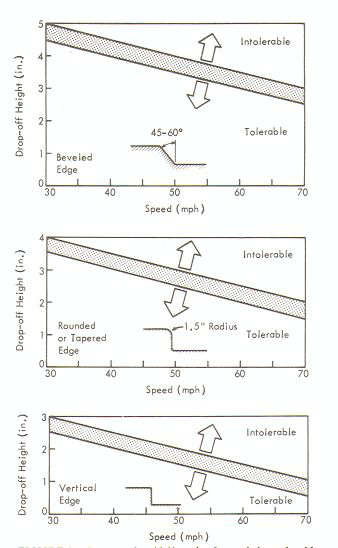

The vertical height difference between the paved surface and the unpaved shoulder is the pavement shoulder drop-off. Drop-offs happen when the unstabilized pavement edges erode, which creates the height difference. Horizontal curves are particularly prone to drop-offs, especially when vehicles stray on to the edge of the travel lane. The illustration at left shows how to measure height and depth of drop-offs.

A drop-off as small as 3 in can create an unsafe condition when the vertical angle is 90 degrees. As an example, once a vehicle crosses from a paved surface onto an unimproved shoulder, the driver’s reaction often is to overcorrect to get back on the road. The overreaction can cause the rear wheel to catch on the shoulder edge and spin the vehicle around. In many instances, drivers attempting to return to the road will veer into the adjacent lane, cross into opposing traffic, or leave on the opposite side of the roadway.

Technique for measuring height and depth of drop-offs.

Application Guidelines

Various shapes and depths of drop-offs can cause more or less of a hazard at various operational speeds. The shape of the drop-off (vertical, rounded, or tapered edges), or vertical angle, in combination with pavement depth can affect the hazard potential of drop-offs. The illustration on the left shows various pavement edge depths and associated operational speeds that research shows to be acceptable.

Drop-off heights and depths in the ‘Intolerable’ range are unsafe.

Design

Applying filled and compacted shoulder material to reduce the drop-off depth has proved a viable method to create a safe condition. A simple, cost-effective solution for agencies is to adopt a standard contract specification requiring a

45-degree angle asphalt fillet along each side of the roadway in all resurfacing projects. The asphalt fillet provides a safer roadway edge and a stronger interface between the roadway and the shoulder.

One way to create a 45-degree wedge is to use a steel wedge or the Safety Edge Maker™, a commercial device being developed by TransTech Systems, Inc. A steel wedge device fabricated by the Georgia DOT (GDOT) Maintenance Division, shown at right, is mounted with a simple two-bolt connection onto the screed end gate. This device has a rounded leading edge that is crucial to providing a smooth finished compaction to the safety edge. The device can also adjust vertically to varying drop-off heights.

Georgia DOT Safety Wedge Hardware.

Effectiveness

Research has shown that drop-off shapes, such as those created by a safety wedge, are a safety device that can reduce the rate of driver overcorrection, head-on, and run-off-road crashes. Thus, the benefit of eliminating the drop-offs is fewer crashes and related injuries—and reduced tort liability.

GDOT evaluated the Safety Edge (see http://safety.fhwa.dot.gov/roadway_dept/pavement/safedge/brochure/) over a 13-mi roadway section. Results showed the Safety Edge Design can be placed on any type of roadway facility as part of the asphalt preventative maintenance paving process. Applying the treatment neither affects finished pavement smoothness, nor increases erosion of the shoulders.

Cost

Agencies can implement the safety edge on any type of roadway facility as part of the asphalt paving process. The Safety Edge implementation cost is approximately less than one percent of the hot-mix asphalt material cost. No specific cost information is available on the Safety Edge Maker™.

Agency Contacts and Further Information

For more detailed information, refer to the following sources:

Frank Julian

FHWA, Resource Center, Atlanta

(404) 562-3689

Frank.Julian@fhwa.dot.gov

Description

The shoulder is the portion of the roadway next to the traveled way. This area is designed to accommodate stopped vehicles (when sufficiently wide) and to provide side support for the roadside in close proximity to the travel lane. Shoulders can be graded (level surface) or useable (rounding on outside edge), as illustrated at left.

Shoulders are a safety feature because they provide space that allows drivers to get out of the travel lane and avoid crashes. This feature is particularly important in horizontal curves where vehicles typically use more of the travel lane than in straight sections.

Cross sections of graded and useable shoulder widths.

Application Guidelines

Shoulder widths can vary from approximately 2 ft on minor rural roads to 12 ft on major roads where the entire shoulder may be stabilized or paved. Agencies should stabilize widened shoulders and ensure roadside slopes comply with AASHTO guidelines. As the figures below illustrate, agencies can widen shoulders on both the inside or outside.

Widening on inside of curve. Widening on the outside of the curve.

Effectiveness

The table below lists estimated reductions in related crashes resulting from widening paved or unpaved shoulders. Related crashes, i.e., those affected by shoulder widenings, include single vehicle run-off-road and multiple vehicle head-on and sideswipe crashes. For example, widening an unpaved shoulder by 4ft (e.g., from 2 ft to 6 ft) would reduce related crashes by an estimated 25 percent. Adding 8-ft paved shoulders to a road with no shoulders would reduce related crashes by an estimated 49 percent. These estimated reductions in related crashes apply only when roadside characteristics (side slope and clear zone) are rebuilt to the condition existing before the shoulder was widened. Although the table below was developed for rural two-lane roads, and not limited to horizontal curves, it is reasonable to expect the major benefit from shoulder widening can also be realized for horizontal curves.

Crash Reductions Related to Shoulder Widening.

Shoulder Widening per Side, (ft) |

Reduction in Related Crash Types (%) |

|

|---|---|---|

Paved |

Unpaved |

|

2 |

16 |

13 |

4 |

29 |

25 |

6 |

40 |

35 |

8 |

49 |

43 |

Description

Agencies should maintain pavements to ensure adequate friction necessary for vehicle braking and maneuvering under both dry and wet conditions. A vehicle will skid during braking and maneuvering when frictional demand exceeds the friction force that can be developed between the tire and the road surface. Horizontal curves are particularly prone to these types of crashes, especially under wet conditions. On road segments where skidding crashes are known to occur, consider applying remedial treatments, including specific asphalt mixtures (type and gradation of aggregate as well as asphalt content), pavement overlays on both concrete or asphalt pavements, and pavement grooving.

Application of skid-resistive pavement surface in curve.

Application Guidelines

Target locations where skidding is a recognized problem and apply either skid-resistive overlays or pavement grooving treatment. Specifically, select sites where vehicle crashes directly result from skidding during wet pavement conditions.

Pavement Surface Overlay Design

Using aggregate that lacks specific particle gradations creates voids on the surface, which promotes better drainage and improves skid resistance. Engineers recommend applying a 1-in, open-graded asphalt concrete to reduce wet pavement crashes. The 1-in maximum gradation improves drainage and skid resistance because it has substantially more voids than the ⅜-in or ½-in maximum open-graded asphalt concrete standard mix.

An agency’s first step is to repair major surface defects (cracks, ruts, etc.) and apply dense-graded asphalt concrete. Next, apply a tack coat to the existing surface before placing the open-graded material. Alternatively, apply a slurry seal using nonpolishing aggregate. A 0.15-ft-thick blanket of the 1-in maximum open-graded asphalt concrete should be sufficient to remove water, increase traction, and ultimately reduce the number of crashes.

Pavement Grooving Design

Pavement grooves increase skid resistance by improving drainage characteristics and creating a rougher pavement surface. Pavement grooving is a technique for installing longitudinal or transverse cuts on the surface to increase skid resistance and reduce the number of wet-weather crashes. Grooves cut in the longitudinal direction have proved most effective in increasing directional control of the vehicle, while transverse grooving is most effective at locations where vehicles make frequent stops. Therefore, applying longitudinal grooving is the commonsense choice for improving safety on horizontal curves.

Because asphalt concrete’s uniform aggregate composition is not conducive to drainage, grooved pavement application is primarily intended for rigid concrete. Agencies can expect a greater accident-reduction result with application at 50 mi/h curves than at 30 or 40 mi/h curves because the major benefit of grooving is to reduce hydroplaning. An accepted application technique is to use a portable grooving machine equipped with carbide-tipped flails to install grooves 3/16 in to 3/8 in wide and 5/32 in to 5/16 in deep, with 8 grooves/ft on a random spacing.

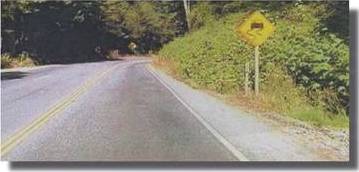

Skid-Resistive Overlay Effectiveness

The rural two-lane curve shown in the figure on the following page was treated with 1-in graded asphalt concrete to improve skid resistance. The appropriate warning sign also was installed. The result was an immediate reduced crash rate—from 16 wet pavement-related crashes in the 13-month period before treatment to two during the first six months following the treatment. Before treatment, 60 percent of crashes along a 2-mile section of treated pavement were wet-pavement related. After the treatment, wet-pavement accidents accounted for only 26 percent.

Rural curve treated with skid-resistive graded asphalt concrete, warning signs, and chevrons.

The New York State DOT (NYSDOT) implemented a program to identify sites statewide with a low skid resistance and treat them with overlays as part of the maintenance program. A site is eligible for treatment if its 2-year wet accident proportion is 50 percent higher than the average wet crash proportion for roads in the same county. Between 1995 and 1997, NYSDOT treated 36 sites on Long Island, which reduced the annually recurring wet road crashes by more than 800. These results, and others throughout the State, support earlier findings that treating wet-road crash locations can reduce this type of crash by 50 percent and reduce total crashes by 20 percent.

The Florida DOT (FDOT) treated a curved freeway ramp with Tyregrip®, a high-friction material illustrated below. This system consists of a highly modified exothermic epoxy resin two-part binder top dressed with a calcinated bauxite with a Polish Stone Value of 70 percent plus. The treatment proved effective at increasing the skid resistance value from 35 to 104. While the FDOT application was to a freeway ramp, the material may be applicable to a higher volume curve with a higher than normal number of wet pavement crashes.

Application of Tyregrip® friction material on a curved ramp.

Pavement Grooving Effectiveness

As indicated, grooved pavements can reduce wet-weather crashes. One study of a California two-lane road with sharp curves found a 72 percent reduction in wet-pavement accidents, but only 7 percent reduction in dry-pavement accidents. There is concern that grooving accelerates pavement wear, but it has not been shown to affect either ride quality or drainage performance.

Cost

Moderate costs are involved in the application of skid-resistive surface treatments. For example a 2-mi section of asphalt overlay cost the California DOT $200,000 in 1996.

Further Information

Technical Advisory T 5040.36 Surface Texture for Asphalt and Concrete Pavements, Federal Highway Administration, Washington, DC, June 17, 2005.

Florida DOT’s experience with Tyregrip, high-friction material for Interstate ramp installation, Charles Holzschuher, phone (352) 955-6341.

| < Previous | Table of Contents | Next > |