U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

.png)

April 2015

FHWA-SA-15-033

View the PDF Version [1.7 MB]

You will need the Adobe Reader to view this PDF.

How is Rumble Strip Noise Measured?

Reducing Noise by Varying Placement

Reducing Noise by Varying Designs

Flexibility and Exceptions for Use of Rumble Strips

Alerting Noise Considerations for the Driver

Issues Affecting In-Vehicle Noise and Vibration

Research on the Effects of Varying Rumble Strip Designs on In-vehicle Noise and Vibration

Case Study: Michigan Noise Study

Longitudinal rumble strips are an effective, low-cost countermeasure for preventing roadway departure crashes, including both run-off-road and opposing-direction crashes. Rumble strips1,2 are milled or raised patterns near the center line or edge line of the roadway that provide both an audible warning (rumbling sound) and a physical vibration to alert drivers that they are crossing into opposing traffic or leaving the roadway. Rumble strips placed underneath center line or edge line striping are often referred to as "rumble stripes."

Rumble Strip Basics. There are two main applications for rumble strips:3

FIGURE 1. Center Line Rumble Strips |

FIGURE 2. Shoulder Rumble Strips |

Noise Effects of Rumble Strips. Challenges to rumble strip implementation exist in areas where the noise caused by vehicles hitting rumble strips is undesirable to the surrounding environment (e.g., nearby residents, nearby businesses, or in sensitive habitat areas). The sound inside the vehicle is important as it provides a warning to a driver that he or she may be leaving the roadway. However, the sound outside the vehicle may be disruptive to those who live near highways because it is intermittent and differs from other "normalized" sounds in those areas (e.g., highway traffic). While these rumble strips are designed to be traversed infrequently (e.g., when a driver drifts from her lane or makes a passing maneuver), citizen acceptance of State or local agency safety countermeasure strategies should be taken into consideration as it can affect the long-term viability of those strategies. Careful attention to design details can result in less nuisance hits on the rumble strips (i.e., vehicle tires crossing the rumble strip when a crash is not imminent).

Transportation agencies use sound-level meters to assess and record noise levels at field locations, as shown in Figure 3. The sound level of rumble strips can be difficult to measure as it occurs more intermittently than normal highway noises. The same basic measurements used to measure highway traffic noise are also used to measure rumble strip noise. The maximum noise level is typically the key consideration for rumble strips, whereas the average noise level, over a period of time, is the key consideration for highway noise. There is currently no method that adequately measures the unique character of rumble strip noise.

The Washington State Department of Transportation (WSDOT) indicates that noise issues result from both the volume and the sound frequency level, as low frequency noise travels farther.6 While the concept of volume is generally understood (more audible sounds typically have a higher decibel level), the frequency isn't generally considered when agencies take into account the "loudness" of sound.

Measuring Rumble Strip Noise Inside the Vehicle

Sufficient noise and vibration levels are needed inside a vehicle to alert drivers they are leaving their lane. These critical factors help ascertain the effectiveness of rumble strips and are typically measured using equipment that is placed inside the vehicle near the driver seat.

Generally speaking, low-frequency waves will travel farther than high frequency waves because there is less energy transferred to the medium through which the sound passes.7 In the case of rumble strips, the "medium" could mean anything that resides in the physical space (e.g., trees, buildings, etc.) between the rumble strips and the noise-sensitive location (e.g., residential housing, schools, commercial offices). Sound levels decrease by 6 decibels (dB) for a point source and 3 dB for a line source8 every time distance between the noise source and the listener is doubled. For example, when a person shouts, a person standing 6 feet away hears the shout at 74 dB. When increasing the distance between the person shouting and the listener to 12 feet, the listener hears the noise at 68 dB.

Figure 4 shows the variables used to assess highway noise as collected by sound level meters. As noise is measured near rumble strip sites, each variable performs an activity to assess the overall noise level, as described below.

FIGURE 4. Components of a Sound Level Meter

The following noise measurement discussion comes from the Impact of Non-Freeway Rumble Strips Phase 1 Final Report performed by Wayne State University for Michigan DOT (MDOT):11

The intensity of sound is measured using either Pascals (Pa) or decibels (dB), which is a logarithmic measure of the effective sound pressure level compared to a standard reference level. Not all frequencies of sound are detected by the human ear. Consequently, sound measurement is typically performed using the "A"- weighted decibel scale (denoted as dBA), which provides the closest approximation to the response of the human ear. The FHWA maintains guidelines for the assessment of roadside traffic noise levels with established threshold levels for Leq (the average sound pressure level) and L10 (the sound pressure level exceeded 10 percent of the time) for various land-use categories.12

Hearing the Difference

While it is desirable to alert drivers with a loud warning inside their vehicles when crossing rumble strips, those who live near highways prefer that rumble strips produce as little noise outside the vehicle as possible. Table 1 compares before and after noise studies conducted by MDOT and relates the noise levels heard in everyday settings.14 This type of information can be used to give the public a frame of reference for potential noise levels. Researchers recorded all measurements at a 50-feet lateral offset and a height of 5 feet above the pavement surface.

| Rumble Strip Depth, inches | Pavement Type | Measured Noise Level Before (dB, ambient traffic) | Measured Noise Level After (dB, while driving on rumble strip) | Comparison Noise Level* |

|---|---|---|---|---|

| 0.25 | Chip seal | 73.3 | 77.5 | Before: Bathtub filling |

| 0.50 | Chip seal | 74.5 | 83.3 | Before: Bathtub filling |

| 0.38 | Hot mix asphalt | 69.0 | 76.4 | Before: Garbage disposal at 2 feet After: Violin at 5 feet |

| 0.56 | Hot mix asphalt | 69.9 | 84.4 | Before: Garbage disposal at 2 feet After: City traffic (inside car) |

| *Acoustical Solutions, Inc., "Noise Level Chart" web page. Available at: http://www.acousticalsolutions.com/noise-level-chart | ||||

Safety Trade-offs

Trade-offs related to safety may occur as a result of any rumble strip design or placement modification. Research has not yet determined the specific extent of these trade-offs.

The strategic consideration and placement of center line, edge line, and shoulder rumble strips is important as practitioners try to balance safety improvements with noise concerns. Standard agency practices may take into account noise concerns while recognizing there may be some unique conditions that need to be assessed per individual locations. Some agencies treat rumble strip installation differently depending on roadway geometry, specifically at horizontal curves and where there are passing zones.

For instance, an agency could place shoulder rumble strips farther from the roadway or replace edge line rumble stripes with shoulder rumble strips to reduce the frequency of contact with the rumble strip or stripe. It should be recognized that tradeoffs related to safety, noise, or other concerns such as bicycle accommodation or pavement preservation may occur as a result of any mitigation effort. For this reason, it is important to evaluate the trade-offs associated with a specific project or location before implementing a solution. Current research does not yet have quantifiable information regarding the specifics of these trade-offs.

Several States have narrowed the focus of public noise complaints to locations where a section of rural highway has suburban characteristics. To address this situation, a single solution or combination of treatments may help to alleviate public concerns. For example:

All three practices mentioned above indicate the desire to exclude rumble strip installation in locations with an increased concentration of residents. MoDOT further recommends omitting edge line rumble strips on major roads where noise may be a significant issue if there is no significant crash history or other risk factors.

Placing center line rumble strips in tight horizontal curves requires additional consideration. Horizontal curvature can produce additional incidental contact (and associated noise) with the rumble strips due to drivers intentionally cutting the curve short or inadvertently off-tracking. This is especially true where the operating speeds do not correlate with the superelevation or where the percentage of large vehicles is high.

Widening the pavement through the curve or designing the curve with a "spiral transition" can reduce the likelihood of vehicles crossing the center or edge line. Center line rumble strips can slow drivers familiar with the roadway as they travel through curves, particularly when the rumble strips are placed in conjunction with shoulder or edge line rumble strips. Where pavement width cannot be adjusted prior to installing rumble strips, an option for center line rumble strips is restriping the pavement either to increase the travel lane width while reducing the shoulder width or to decrease the lane width for a greater median separation.

For edge line or shoulder rumble strips, a method to mitigate this potential concern is to offset shoulder or edge line rumble strips in the specific locations where noise might be problematic.

Rumble Strip Gaps for Intersecting Routes

Several agencies terminate center line and shoulder or edge line rumble strips in the proximity of intersections to mitigate noise concerns.

Agencies typically discontinue rumble strips in the vicinity of intersections and major driveways. Rumble strips are omitted within the intersection itself, where they would be crossed by turning traffic or entering vehicles. Additionally, edge line or shoulder rumble strips are often discontinued on each approach in locations with noise concerns to reduce noise from drivers who slow and pull to the right in advance of a right turn.

Placement of rumble strips in passing zones will result in expected noise from passing maneuvers. With some of the very first installations, agencies did not place rumble strips in passing zones but quickly discovered that a continuous application was necessary to achieve the safety benefits. States have identified that head-on and opposite-direction-sideswipe crashes are as likely to occur in passing zones as they are in no passing zones. Most agencies mitigate noise by terminating rumble strips at intersections and driveways while still installing center line rumble strips in passing zone locations.18

Varying Designs: Commercial Vehicle Use

It may be necessary to increase rumble strip dimensions where large commercial vehicles are frequent road users. According to NCHRP Report 641, noise in the passenger compartment of a commercial vehicle generated by rumble strips has a greater effect in alerting the driver than the vibration.

Much like rumble strip placement, rumble strip design can have an impact on the amount of noise generated by vehicles as they pass over the rumble. Though placement is more likely to have a significant effect, WSDOT comments that, "agencies can slightly affect the volume of the noise generated by rumbles through design modification."19

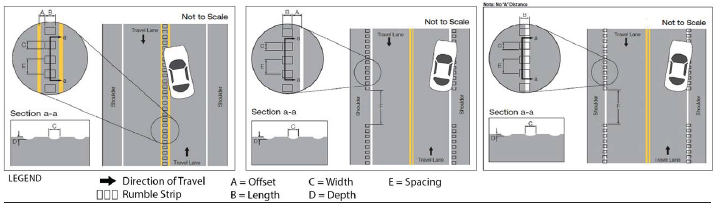

Agencies with established rumble strip implementation practices may have standard dimensions for construction. While the actual dimensions vary by agency, Figure 5 indicates the standard nomenclature for center line, edge line, and shoulder rumble strip dimensions.20, 21

WSDOT has received noise complaints about their standard rumble strip dimensions, and, as a result, the agency has occasionally installed rumble strips with a shallower 3/8 inch design. The agency is also experimenting with wider longitudinal spacing between rumble strips.22 Likewise, PennDOT recognized the need to fine-tune rumble strip designs and allows rumble strip depth (D) to be decreased from 1/2 inch to 3/8 inch in passing zones.23

FIGURE 5. Center Line, Shoulder, and Edge Line Rumble Strips and Stripes Dimension Terminology

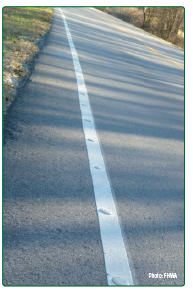

FIGURE 6. Raised Edge Line Rumble Strip |

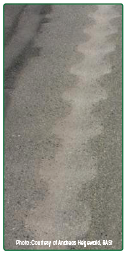

FIGURE 7. Sinusoidal Rumble Strip |

As agencies begin providing rumble strips on the edge of the travel way, they must assess the advantages and disadvantages associated with shoulder versus edge line rumble strips. WSDOT and PennDOT prefer shoulder rumble strips, partially to mitigate the effect of noise associated with rumble strip hits.24,25 While edge line rumble stripes tend to have more hits due to their placement closer to the traveled way, they have the added benefit of improved wet weather and nighttime visibility, greater pavement marking durability, and earlier warning to motorists.

Additionally, an agency could move shoulder rumble strips further from the travel way to reduce the number of hits, but doing so may negatively impact bicyclist use of the shoulder.

Several agencies have used modified rumble strip designs in an attempt to reduce noise levels. Some designs, like raised edge line rumble strips (shown in Figure 6), reduce external noise but do not provide the same level of internal noise and vibration as typical milled rumble strips. Currently, agencies are investigating rumble strip designs that provide sufficient alerting internal noise, while reducing external noise, as described below.

Sinusoidal Rumble Strips

California Department of Transportation (Caltrans) is testing a sinusoidal rumble strip as a quieter design alternative (shown in Figure 7). In their March 2012 preliminary investigation report, Caltrans states that "external noise from sinusoidal rumble strips is 3 to 7 decibels quieter than rectangular strips," and concluded that sinusoidal rumble strips' external noise is only 0.5 to 1 decibels above ambient noise.26 These measurements were taken by placing a microphone on one side of the two-lane road at a distance of approximately 25 feet from the roadway center line and at a height of approximately 4 feet above the road surface.

A recent Minnesota noise study compared two 8-inch sinusoidal designs against a conventional rumble strip of 16-inches.27 The study included a passenger car, pickup truck, and tractor trailer traveling at speeds of 30 mph, 45 mph, and 60 mph. One of the sinusoidal shapes had depth and spacing dimensions similar to the conventional rumble strips and the interior noise differential from both these rumble strips designs was 6 dBA or more for both the passenger car and the pickup truck at 45 mph.

Most interestingly, the study concluded that overall exterior noise produced by both of the 8-inch sinusoidal rumble strips was less than that produced by the 16-inch conventional rumble strips. Since the study did not include an 8-inch conventional design, it is not clear if the sinusoidal shape is the reason for the difference in exterior noise levels. A number of European studies have also tested sinusoidal shapes, with varying results. All studies concluded that sinusoidal rumble strips produced marginal to no perceptible increase in external maximum noise level. Several Norwegian studies within this group indicated that the sinusoidal rumble strips provided adequate internal noise needed to alert an inattentive or drowsy driver. However, the 2013 Swedish study found that their sinusoidal rumble strips generated lower internal noise in the car and less vibration than conventional strips.28 These studies' conflicting results may be due to differences in rumble strip design, strip dimension, and/or weight of vehicles used in the study.

Widely Spaced Rumble Strips

WSDOT has an ongoing rumble strip research project that has installed several experimental patterns. They are currently experimenting with wider spacing between strips and shallower depth (Dimensions E and D, respectively, as shown in Figures 5) in an attempt to reduce the roadside noise associated with rumble strips. The agency indicates that there has not been sufficient time to enable a performance study of these installations.29

Safety First...

Road user safety should be emphasized as practitioners respond to public concerns.

As discussed previously, several agencies practice flexibility with respect to rumble strip placement and design. They may even choose not to install rumble strips, although general practice or policy recommends rumble strip installation at a specific location.

WSDOT does not provide specific guidance restricting rumble strip installation (e.g., lane width or functional class); rather, it suggests assessing each road or location independently. As an example, the agency has learned to generally discontinue rumble strips prior to both intersections and narrow bridges due to noise concerns.

MDOT's Road Design Manual states that "if safety concerns outweigh other issues such as noise and bicycle use, non-freeway shoulder and centerline corrugations can be considered for use on roadways that do not meet [other given] criteria."30 This gives flexibility for agency staff to consider installing rumble strips on roadways with narrower shoulders or a low functional classification.

Both MDOT and MoDOT tend to exclude rumble strip installation in locations with high resident concentrations. Exclusions are based primarily on functional classification and posted speed limits. This works well for Michigan and Missouri because these States have very few rural roads with speed limits less than 55 mph.

If agencies are trying to systemically implement rumble strips statewide, they should consider the need for public outreach from both a statewide and a local perspective. Outreach efforts should take into account local citizens' understanding and knowledge of rumble strips and may vary in different regions of the state.

Practitioners should be willing to modify the design and placement of rumble strips on an as-needed basis (i.e., after assessing safety impacts) and to educate the public about treatment options. Some surveys have shown that informed citizens often consider improved safety worth the increase in external noise, and that residents become accustomed to the increased noise fairly quickly.31

An example of an often heard public comment follows, as does a scripted message and potential solutions:

Obstacle: "The noise level at my house will be unbearable when you install rumble strips!"

Message: For center line, shoulder, and edge line rumble strips, noise is generated only when vehicles leave their travel lane. Studies have also shown that when rumble strips end approximately 650 feet prior to residential or urban areas, the noise impacts are tolerable; at a distance of 1,640 feet, the noise generated from rumble strips is negligible.32

Potential Solutions: To address these complaints, some agencies have increased the offset of the rumble strip from the edge line to decrease the incidence of vehicles falsely traversing the rumble strips. Other transportation agencies have removed sections of the rumble strips that receive frequent nuisance hits.

The amount of noise needed to alert drivers is an important human factors issue in need of further research. Recommendations are available regarding the minimum amount of noise and vibration needed to alert drivers, including those who are drowsy or distracted. Existing research shows that a distracted driver will likely notice a 3 dBA increase above the ambient in-vehicle sound level, but that this change may be insufficient to alert a drowsy driver. A 6 dBA sound level increase is more likely to target all drivers sufficiently, including inattentive, distracted, and drowsy or fatigued drivers, with the necessary stimulus to correct their steering.

NCHRP 641 recommends the following three noise level increases in ambient in-vehicle noise levels for effective rumble strips:

Even though these guidelines are available, common practice is typically based on engineering judgment.

Many vehicle characteristics and driver behaviors or traits impact the amount of noise and vibration heard and felt inside the vehicle, which ultimately influences rumble strip effectiveness.

A vehicle's type, size, age, and the quality of its suspension system all contribute to the level of interior noise and ride smoothness. Couple these baseline readings with the noise and vibrations that occur as the vehicles crosses over rumble strips, and there are thousands of possible noise and vibration level combinations that can occur when any one variable is changed. Some studies have concluded that larger commercial vehicles may be affected less by rumble strip noise and vibration than small passenger vehicles.

The effect of driving behavior on rumble strip effectiveness exhibits yet another set of variables. There are a host of possibilities that may affect the vehicle's angle of departure when leaving the lane, such as whether a driver is drowsy, looking at the radio or cell phone, or impaired. This angle of departure plays an important role in rumble strips' effectiveness. The slighter the departure angle, the more contact that vehicle tires have with rumble strips, leading to longer noise and vibration warnings. As a vehicle slowly drifts from the lane, the resulting rumble strip warning is maximized and gives the driver more notification and time to react. Rumble strips are not intended to be effective where lane departure angles are large, such as when the driver adjusts the steering wheel sharply to avoid an object in the road.

Lastly, vehicle speed may have a role in the in-vehicle noise and vibration levels. As speeds increase, the noise pitch and vibration frequency vary, affecting the degree to which drivers feel, hear and, ultimately, react to rumble strips.

NCHRP 641 cites a field experiment that was conducted to use noise data and statistical models to determine the optimum dimensions for rumble strips in various conditions. Researchers collected sound level data on a wide range of rumble strip dimensions in six States. They used ordinary least squares linear regression models to predict the in-vehicle sound level differences.

The results of the original regression model showed that milled rumble strips are associated with a higher sound level difference than rolled, while asphalt pavement surface is associated with a higher sound level difference than concrete. Additional prediction models have been developed to better explain the sound level difference pertaining to specific indicator variables. Any agency can use these prediction models to determine the optimum rumble strip dimensions for given base conditions.35

Many auto manufacturers offer in-vehicle lane departure prevention systems or lane keeping assist systems. Both types of systems allow for the driver to override the automated warnings or corrections. The process these technologies use to warn drivers and prevent their vehicles from leaving their travel lane varies. In some systems, on- or in-vehicle cameras and processing systems monitor the distance between the vehicle and lane pavement markings. If the vehicle begins drifting toward the center or edge line markings, and the turn signal is not engaged, the prevention system may either:

Since these technologies work by assessing the distance between the vehicle and the lane markings, it stands to reason that the systems don't work as well when pavement markings are not present, have faded, or when rain, snow, or ice impede the markings' visibility.

Center line, edge line, and shoulder rumble strips effectively reduce roadway departure crashes and can be modified to address undesirable noise concerns. External noise may be mitigated by eliminating rumble strips along an entire noise-sensitive corridor or at specific locations where nuisance hits are prevalent (e.g., curves, intersections, passing zones). Varying rumble strip dimensions or altering the spacing between rumble strips can also reduce exterior noise, although this will likely reduce the countermeasure's effectiveness. Most promisingly, alternative designs (e.g., sinusoidal rumble strips) may maximize the interior vibration and alerting noise while minimizing the exterior noise. These rumble strip adaptations and alternatives can make this countermeasure adaptable to most highway systems where roadway departure crashes are prevalent.

It is critical to continue installing rumble strips to prevent highway fatalities during the transition period as automated vehicle warning systems are integrated into the fleet and perfected to perform this alerting task without the associated noise external impacts.

MDOT and Wayne State University conducted a controlled field study in 2012 to evaluate increases in noise produced by rumble strips on rural two-lane highways in Michigan as a function of rumble strip depth and pavement surface type. The research team chose 12 sites on MDOT's two-lane rural highways where rumble strips were installed in 2010. The study locations were selected to provide a representative balance between various roadway and rumble strip characteristics. Each study location had a posted speed limit of 55 mph (which is in accordance with MDOT policy).

The research team recorded rumble strip hits using a digital sound meter with a foam windscreen at a roadside location 50 feet away from the roadway center line at a height of 5 feet above the pavement surface, as recommended by the FHWA for roadside noise measurement.

Pavement-Noise Results: The noise study results concluded that the noise produced by the test vehicle when in contact with the rumble strips varied based on the pavement surface type. Chip sealed pavement surfaces provided a mean peak noise measurement that was 1.92 dBA greater than that measured on hot mix asphalt pavements.

Rumble Depth-Noise Results: The milled depth of the rumble strip corrugation had the greatest effect on the noise produced when contact was made with the rumble strips, although the impact of depth was not linear, as evidenced by the sharp increase in peak noise at depths of 0.5 inches and above. The mean peak noise produced by center line rumble strips with depths of at least 0.5 inches was 84.62 dBA compared to 77.82 dBA for center line rumble strips depths that were less than 0.5 inches, representing a 6.8 dBA difference. Center line rumble strips with depths of at least 0.5 inches exceeded the noise levels produced by tractor trailers by 1.54 dBA. Within the range of observed depth values (0.25 inch to 0.69 inch), noise levels were found to increase by an average of 1.25 dBA per every 0.0625 inch increase in rumble strip depth.

Recommendation: To prevent unnecessarily high levels of unwanted roadside noise, the study team recommends that rumble strips be milled at depths between 0.25 and 0.50 inches.

Source: T.K. Datta, T.J. Gates, and P.T. Savolainen, Impact of Non-Freeway Rumble Strips – Phase 1, Report #RC-1575, (Lansing, MI: Michigan Department of Transportation, June 2012). Available at: http://www.michigan.gov/documents/mdot/MDOT_Research_Report_RC1575_Report_394019_7.pdf.

The following resources provide more details related to rumble strip noise, use, and design:

FHWA, Office of Safety:

Cathy Satterfield

cathy.satterfield@dot.gov

(708) 283-3552

FHWA, Office of Environment:

Mark Ferroni

mark.ferroni@dot.gov

(202) 366-3233

For more information on Rumble Strip Implementation Guide: Addressing Noise Issues on Two-Lane Roads, visit:

FHWA Office of Safety

http://safety.fhwa.dot.gov/

1 FHWA, "Technical Advisory T 5040.39: Shoulder and Edge Line Rumble Strips," Revision 1, November 7, 2011. Available at: http://safety.fhwa.dot.gov/roadway_dept/pavement/rumble_strips/t504039/ [ Return to note 1. ]

2 FHWA, "Technical Advisory T5040.40: Center Line Rumble Strips," Revision 1, November 7, 2011. Available at: http://safety.fhwa.dot.gov/roadway_dept/pavement/rumble_strips/t504040/ [ Return to note 2. ]

3 FHWA Office of Safety, "Rumble Strips and Stripes" web page. Available at: http://safety.fhwa.dot.gov/roadway_dept/pavement/rumble_strips/ [ Return to note 3. ]

4 D. J. Torbic, J. M. Hutton, et al., NCHRP Report 641: Guidance for the Design and Application of Shoulder and Centerline Rumble Strips, Transportation Research Board, National Cooperative Highway Research Program (Washington, DC: TRB, 2009), Table 67. Available at http://onlinepubs.trb.org/onlinepubs/nchrp/nchrp_rpt_641.pdf [ Return to note 4. ]

5 Ibid. [ Return to note 5. ]

6 Interview with Dave Olsen, Matthew Enders, T.J. Nedrow, Ian Macek, Tim Sexton, Mark Russell, Jeff Uhlmeyer, and Steve Bennett of Washington State DOT, conducted on October 30, 2012. [ Return to note 6. ]

7 Physics Lab Online, "Introduction to Sound," available at: http://dev.physicslab.org/Document.aspx?doctype=3&filename=WavesSound_IntroSound.xml [ Return to note 7. ]

8 A point source is a single identifiable, localized source of sound. A line source is a source of sound that emanates from a linear (one-dimensional) geometry. [ Return to note 8. ]

9 FHWA, Measurement of Highway-Related Noise, FHWA-PD-96-046 (Washington, DC: FHWA, 1996). Available at: https://www.fhwa.dot.gov/environment/noise/measurement/measure.cfm [ Return to note 9. ]

10 Ibid. [ Return to note 10. ]

11 TT.K. Datta, T.J. Gates, and P.T. Savolainen, Impact of Non-Freeway Rumble Strips – Phase 1, Report #RC-1575, (Lansing, MI: Michigan Department of Transportation, June 2012). Available at http://www.michigan.gov/documents/mdot/MDOT_Research_Report_RC1575_Report_394019_7.pdf. [ Return to note 11. ]

12 Electronic Code of Federal Regulations, Title 23, Chapter 2, Subchapter H, "Part 772 – Procedures for Abatement of Highway Traffic Noise and Construction Noise." Web address: http://www.ecfr.gov/cgi-bin/text-idx?SID=63a6a40884fe0528ccf4896522f4bc4d&node=23:1.0. 1.8.44.0.1.11.31&rgn=div9 [ Return to note 12. ]

13 Caltrans Division of Environmental Analysis, The Effects of Highway Noise on Birds (Environmental BioAcoustics, LLC: 2007). Available at: http://www.dot.ca.gov/hq/env/bio/files/caltrans_birds_10-7-2007b.pdf [ Return to note 13. ]

14 T.K. Datta, T.J. Gates, and P.T. Savolainen, Impact of Non-Freeway Rumble Strips – Phase 1, Report #RC-1575, (Lansing, MI: Michigan Department of Transportation, June 2012). Available at http://www.michigan.gov/documents/mdot/MDOT_Research_Report_RC1575_Report_394019_7.pdf [ Return to note 14. ]

15 Interview with Jill Morena, Tracie Leix, Deirdre Thompson, Curtis Bleech, Andy Bennett, Tim Croze, Marc Beyer, and Erin Chelotti of Michigan DOT and Tim Gates of Wayne State University, conducted on May 22 & 23, 2013. [ Return to note 15. ]

16 MoDOT, Engineering Policy Guide, Section 626. Available at: http://epg.modot.org [ Return to note 16. ]

17 Interview with Gary Modi, Chris Speese, Lydia Peddicord, Scott Nazar, Brian Sanders, and Josh Freeman of PennDOT, conducted on August 27, 2013. [ Return to note 17. ]

18 FHWA, "Technical Advisory T5040.40: Center Line Rumble Strips," Revision 1, November 7, 2011. Available at: http://safety.fhwa.dot.gov/roadway_dept/pavement/rumble_strips/t504040/ [ Return to note 18. ]

19 Interview with Dave Olsen, Matthew Enders, T.J. Nedrow, Ian Macek, Tim Sexton, Mark Russell, Jeff Uhlmeyer, and Steve Bennett of Washington State DOT, conducted on October 30, 2012. [ Return to note 19. ]

20 FHWA, "Technical Advisory T5040.40: Center Line Rumble Strips," Revision 1, November 7, 2011. Available at: http://safety.fhwa.dot.gov/roadway_dept/pavement/rumble_strips/t504040/ [ Return to note 20. ]

21 FHWA, "Technical Advisory T 5040.39: Shoulder and Edge Line Rumble Strips," Revision 1, November 7, 2011. Available at: http://safety.fhwa.dot.gov/roadway_dept/pavement/rumble_strips/t504039/ [ Return to note 21. ]

22 Interview with Dave Olsen, Matthew Enders, T.J. Nedrow, Ian Macek, Tim Sexton, Mark Russell, Jeff Uhlmeyer, and Steve Bennett of Washington State DOT, conducted on October 30, 2012. [ Return to note 22. ]

23 Interview with Gary Modi, Chris Speese, Lydia Peddicord, Scott Nazar, Brian Sanders, and Josh Freeman of PennDOT, conducted on August 27, 2013. [ Return to note 23. ]

24 Interview with Dave Olsen, Matthew Enders, T.J. Nedrow, Ian Macek, Tim Sexton, Mark Russell, Jeff Uhlmeyer, and Steve Bennett of Washington State DOT, conducted on October 30, 2012. [ Return to note 24. ]

25 Interview with Gary Modi, Chris Speese, Lydia Peddicord, Scott Nazar, Brian Sanders, and Josh Freeman of PennDOT, conducted on August 27, 2013. [ Return to note 25. ]

6 Caltrans Division of Research and Innovation, Traffic Noise Generated by Rumble Strips, (CTC and Associates, LLC, 2012). Available at: http://www.dot.ca.gov/research/researchreports/preliminary_investigations/docs/rumble_strip_noise_preliminary_investigation_3-5-12.pdf [ Return to note 26. ]

27 E. Terhaar and D. Braslau, Rumble Strip Noise Evaluation, MN/RC 2015-07, Minnesota Department of Transportation Research Services & Library (St. Paul, MN: MNDOT, February 2015). Available at: http://www.dot.state.mn.us/research/TS/2015/201507.pdf [ Return to note 27. ]

28 A. Vadeby, A. Anund, U. Björketun, and A. Carlsson. VTI Report 790: Safe Accessibility: Summarised Results. 2013. Available at: http://www.vti.se/en/publications/pdf/safeaccessibility-summarised-results.pdf [ Return to note 28. ]

29 Interview with Dave Olsen, Matthew Enders, T.J. Nedrow, Ian Macek, Tim Sexton, Mark Russell, Jeff Uhlmeyer, and Steve Bennett of Washington State DOT, conducted on October 30, 2012. [ Return to note 29. ]

30 Michigan DOT, Road Design Manual. Available at: http://mdotcf.state.mi.us/public/design/englishroadmanual/ [ Return to note 30. ]

31 FHWA, "Technical Advisory T 5040.39: Shoulder and Edge Line Rumble Strips," Revision 1, November 7, 2011. Available at: http://safety.fhwa.dot.gov/roadway_dept/pavement/rumble_strips/t504039/ [ Return to note 31. ]

32 G. Bahar, J. Wales, and L. Longtin-Nobel, Synthesis of Best Practices for the Implementation of Shoulder and Centerline Rumble Strips, Transportation Association of Canada (TAC), 2001. [ Return to note 32. ]

33 Interview with John Miller, Joe Jones, Ashley Reinkemeyer, Michael Curtit, and John Donahue, Missouri DOT, conducted on June 5-6, 2013. [ Return to note 33. ]

34 NCHRP 641: Guidance for the Design and Application of Shoulder and Centerline Rumble Strips. 2009. Available at: http://onlinepubs.trb.org/onlinepubs/nchrp/nchrp_rpt_641.pdf [ Return to note 34. ]

35 D. J. Torbic, J. M. Hutton, et al., NCHRP Report 641: Guidance for the Design and Application of Shoulder and Centerline Rumble Strips, Transportation Research Board, National Cooperative Highway Research Program (Washington, DC: TRB, 2009). Available at: http://onlinepubs.trb.org/onlinepubs/nchrp/nchrp_rpt_641.pdf [ Return to note 35. ]