U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

U.S. Department of Transportation

Federal Highway Administration

FHWA-SA-16-021

View the PDF Version [2 MB]

High friction surface treatments (HFST) are an effective countermeasure for improving pavement friction to meet friction demand at curves on both asphalt and concrete surfaces. HFST can increase friction values on bridge decks far above those achieved by new asphalt or concrete, as well as extend its lifespan.

Iowa Department of Transportation (IDOT) chose to install their introductory HFST application on a bridge over the Cedar River. The 5-in-1 structure comprises four bridges: north and southbound I-380, eastbound "A" Avenue, westbound "F" Avenue, and a dam. Located just west of the river, the curve is a part of the six-lane urban I-380 that runs through Cedar Rapids and carries approximately 85,000 vehicles per day. Several large corporations surround this area and ship supplies nationwide, contributing to the approximately 7,800 heavy trucks that use the bridge daily.

There are multiple factors that contribute to the crash risk at this location. Several ramps feed traffic onto I-380 in close proximity to one another, forcing vehicles to make quick lane changes. In addition, the travel speeds were excessive for the curve radius and existing pavement friction. As a result, drivers, maintenance staff, and police officers frequently reported that the bridge deck was slick, especially when wet.

These factors contributed to more than 54 crashes reported between the spring of 2008 and the spring of 2012, of which 28 were injury crashes. The crashes caused significant traffic delays due to high traffic volumes on the bridge. Eight of the 54 crashes involved a semi-trailer, one of which caught media attention when it toppled over the side of the bridge and caught fire below. To further evaluate the crash causes and explore potential solutions, IDOT conducted a road safety audit (RSA) at this location. During the field reviews, friction tests indicated skid numbers in the 30s and 40s. To address the pavement friction issues, the RSA team recommended HFST as a possible countermeasure.

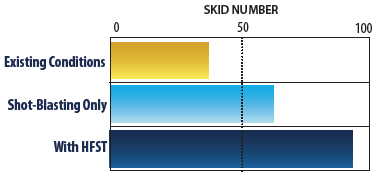

IDOT staff considered and compared multiple pavement friction restoration technique solutions that would reduce crashes significantly and quickly. One potential solution was shot-blasting, which may temporarily increase friction values into the low 60s. IDOT also considered repaving this portion of I-380, but the expense was greater than available funding. Further, the new surface could have polished quickly due to the high traffic volumes, volumes of heavy trucks, and frequent lane changes just as the existing pavement had experienced.

By contrast, the IDOT team recognized that HFST offered several advantages:

The more we considered HFST, the more it looked like the clear answer.

— Jerry Roche, FHWA

In spite of these benefits, IDOT's materials and maintenance personnel had reservations about installing the treatment on a multilane interstate bridge, in a high profile location where multiple crashes had occurred, with high traffic and truck volumes.

Also, IDOT were not aware a documented history of successfully applying HFST to bridge decks in states with cold climates. To convince their staff of its merits, IDOT installed HFST on their office campus grounds to observe the installation process and test the results.

In June 2012, IDOT installed a single layer of HFST at this location after existing pavement was shot-blasted to provide better HFST adhesion. Additional work included deck patching, pavement marking removal, joint covering, shot-blasting, and automated HFST application.

Immediately after installation, IDOT measured friction values in the 90s and low 100s and found that they stayed approximately the same several months later. When tested again over a year later, they found that values ranged from the 80s to low 100s. Figure 3 displays comparative pavement friction levels taken at this location for:

In the one year directly after HFST installation, 4 crashes occurred, only one involving an injury. The project cost totaled $494,000 for 1.8 lane miles of roadway, or 0.3 miles over six lanes in the north and southbound directions. The treatment is expected to have a lifespan of 8 to 10 years, yielding an approximate benefit-cost ratio of 3.8.

Shortly after installation, HFST received positive feedback from both agency personnel and the public. Cedar Rapids police officers expressed gratitude for the HFST installation because bridge crashes are now less frequent and less severe. The treatment has held up so well over the years since installation that IDOT's maintenance staff now advocates for the countermeasure; they have asked to use it at other locations experiencing similar issues. Furthermore, the application brought public recognition to IDOT for solving a major safety concern and the Cedar Rapids Gazette2 praised the countermeasure for reducing crashes and improving safety on the bridge.

For more information:

Joseph Cheung

FHWA Office of Safety

joseph.cheung@dot.gov

Frank Julian

FHWA Resource Center

frank.julian@dot.gov

1 Federal Highway Administration, Every Day Counts 3 Initiative, "High Friction Surface Treatments" web page. Available at: https://www.fhwa.dot.gov/innovation/everydaycounts/edc-2/hfst.cfm

2 Erin Jordan, "Stretch of I-380 in Cedar Rapids treated with polymer sees reduction in crashes," The Cedar Rapids Gazette, November 27, 2013. Accessible at: http://www.thegazette.com/2013/11/27/stretch-of-i-380-in-cedar-rapids-treated-with-polymer-sees-reduction-in-crashes?+GazetteOnlineLocalNews+(TheGazette.com+Local+News)