U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

U.S. Department of Transportation

Federal Highway Administration

FHWA-SA-15-056

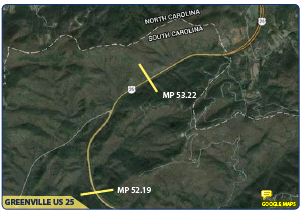

A one-mile section of US 25 in Greenville County had been a cause for concern for the South Carolina Department of Transportation (SCDOT) for many years. Located in rural, mountainous terrain, and often subject to inclement weather including rain, snow, ice, and fog, US 25 carries traffic on two lanes in each direction and is separated only by a damaged and brittle concrete barrier. US 25 changes dramatically, from a relatively straight road in North Carolina directly to this particular section in South Carolina with horizontal and vertical curves and a 6 percent grade. US 25 has a speed limit of 55 mph and carries approximately 10,000 vehicles per day with heavy truck traffic.

SCDOT discovered a number of factors contributing to the high crash rates along this short section of US 25. One significant factor was that the concrete barrier's design did not allow for proper drainage, channeling water to the driving lane and shoulder. Speeding, inadequate pavement superelevation, and sight distance constraints also contributed to the safety issues at this location.

In 2000, SCDOT considered funding a major reconstruction project which involved replacing and updating the barrier wall and modifying the roadway's superelevation and drainage structures. However, with the project's estimate coming in at nearly $5 million, this project was unlikely to happen. Both costly and lengthy, the overall project development timeline for this alternative would have spanned approximately three years, and would have involved an extensive work zone and detour which would have inconvenienced local residents and drivers traveling through this area.

Over the years, low-cost measures of additional signing and markings were added along US 25, but these did not adequately address the excessive speeds and drainage issues, and the resulting safety improvement was minimal at best. At one point, a dynamic message sign (DMS) was installed to display a regulatory 45 mph speed limit during rainy conditions. However, due to the rural nature of this road segment and the wide road template, speeds remained excessive.

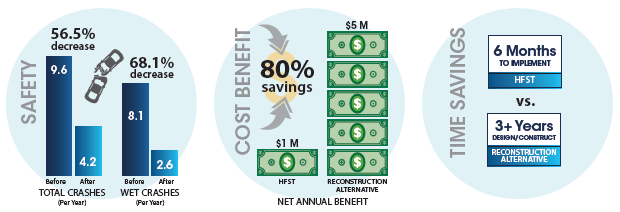

In 2008, a High Friction Surface Treatment (HFST) was applied to this curvy stretch of US 25. SCDOT had used this pavement treatment on ramp segments to increase skid resistance in locations where friction demand was high, but this one-mile project was the largest application to date, and at the time, it was unclear whether HFST would mitigate the hydraulic issues drivers experienced on this segment. With the planning process and installation complete in approximately six months, the HFST project cost SCDOT $1 million, which was 80 percent less than the previously considered reconstruction project.

A before and after study evaluating the HFST project's success on US 25 revealed significant safety benefits, with a 68 percent reduction in wet crashes and a 56 percent reduction in total crashes. Six years after HFST installation, SCDOT reports the pavement treatment is holding up very well, considering the high exposure to snow plowing.

To develop its current HFST specification, SCDOT used the AASHTO specification as the base model and integrated pieces from other States' specifications as well as their own experiences with the treatment. While their HFST specification is still evolving, SCDOT believes it strikes a good balance between quality materials and application, while still maintaining reasonable contractor expectations and competitive bidding.

For more information:

| Joseph Cheung FHWA Office of Safety joseph.cheung@dot.gov |

Frank Julian FHWA Resource Center frank.julian@dot.gov |

Joey Riddle, Safety Engineer South Carolina DOT RiddleJD@scdot.gov |