U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

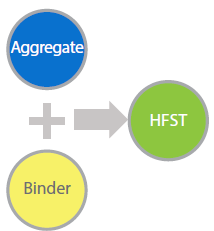

HFST improves roadway surface friction by increasing pavement roughness. The treatment is composed of a thin layer of specially engineered, durable, high-friction aggregate bonded to the existing pavement by a thermosetting polymer resin binder as illustrated in Figure 4. The binder locks the aggregate firmly in place, creating an extremely rough, hard, durable surface capable of withstanding everyday roadway demands, such as heavy braking and even snowplowing. In fact, snowplowing can further roughen HFST by breaking the aggregate into more angular bits, which increases the pavements friction level even further.21, 22 This section will discuss the various aggregates and binders that can be used for HFSTs.

Figure 4. HFST Components.

HFST aggregates, typically between 3 to 4 mm in size, come in different sizes with varying friction values and durability. Once the binder has been applied to the pavement surface, the aggregate is spread on top of the binder. Currently, calcined bauxite is the most widely used HFST aggregate in the United States and the only aggregate recommended by FHWA

The National Center for Asphalt Technology (NCAT) report released in 2015 titled High Friction Surface Treatment Alternative Aggregates Study showed that of all aggregates tested, the calcined bauxite, shown in Figure 5, produced the greatest initial and long-term friction values, proving it to be the most durable and wear resistant aggregate used for HFST.23 All aggregates tested, and a description of their composition, included:

HFST binder choice may be influenced by cost, climate, road volume, binder availability, and vendor selection. HFST's overall durability can vary as a result of the chosen binder, which are spread on the pavement surface before aggregate is applied.

Typical HFST binders are the following:24

Epoxy binder systems typically take the longest to cure in cooler temperatures. Catalyzed binder systems such as the MMA and polyester systems can be adjusted to cure faster in cooler temperatures. The curing times discussed in this section are estimated based on average ambient temperatures (approximately 70 degrees Fahrenheit). In comparatively colder or warmer climates, ideal binders for projects may vary due to temperature fluctuations.25 Table 3 summarizes binder curing times.

| Binder | Quickest Curing Time* | Curing Temperature |

|---|---|---|

| Epoxy-Resin | 3 – 4 hours | 70+F |

| Rosin-Ester | As soon as it reaches ambient temperature | ambient temperature |

| Polyurethane-Resin | 2.5 hours | |

| Methyl Methacrylate | 1.5 hours | <20F to 100+F |

| Polyester-Resin | 2 hours | <40F to 100+F |

21 FHWA's Every Day Counts HFST - A Road Surface Treatment for Critical Safety Spot Locations that Helps Vehicles Stay in Their Lane. Available at: https://www.fhwa.dot.gov/everydaycounts. [ Return to note 21. ]

22 FHWA's High Friction Surface Treatments Frequently Asked Questions. Publication No. FHWA-CAI-14-019. [ Return to note 22. ]

23 National Center for Asphalt Technology, Asphalt Technology E-News. Volume 26, Number 2. Available at: http://www.eng.auburn.edu/research/centers/ncat/info-pubs/newsletters/fall-2014/traction.cfml. [ Return to note 23. ]

24 American Traffic Safety Services Association, Safety Opportunities in High Friction Surfacing. February 2013. [ Return to note 24. ]

25 American Traffic Safety Services Association, Safety Opportunities in High Friction Surfacing. February 2013. [ Return to note 25. ]

26 Ibid. [ Return to note 26. ]

| < Previous | Table of Contents | Next > |