U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

This chapter identifies and assesses practices and programs for the maintenance of pedestrian facilities. It begins with the basics of how pedestrian facilities fall into disrepair and how jurisdictions inspect those facilities. It includes a discussion of differences in practices from community to community and from state to state (including effect of climates). The chapter also includes a discussion on the American with Disabilities Act (ADA), as well as state laws and their impact on the provision of maintenance. The chapter draws on the literature review, community discussions and other resources contained in Chapter 1 and forms the basis for the recommendations included in the Guide.

For the purposes of this research report and for the Guide, pedestrian facilities that will be addressed include sidewalks and walkways, shared use paths, crosswalks, curb ramps, and pedestrian signals. Other types of pedestrian facilities exist, such as street lighting and paved shoulders, but are maintained as part of a larger street or highway projects with the maintenance for pedestrians considered incidental to the maintenance needs required by other users of the facilities.

Sidewalks and shared use paths are the main types of pedestrian facilities that serve pedestrians between intersections. Occasionally walkways or footpaths exist in separate corridors that are not part of the street right-of-way. Surfacing is typically concrete for sidewalks and asphalt pavement for shared use paths. However, there are communities that rely entirely on concrete surfacing for shared use paths and others that rely on asphalt for sidewalks. Furthermore, asphalt pavement is often used as a temporary pavement for patching concrete sidewalks.

Bricks and pavers are also used for pedestrian facilities. In some communities these materials are used to preserve a traditional material and appearance in a downtown or historic district. In some settings pavers are used to border concrete sidewalks. Although these materials tend to be very durable, they have some unique maintenance issues which will be discussed briefly in this research, but more thoroughly covered in the Guide itself. Briefly here are the main types of sidewalk materials.

Image 1: A concrete sidewalk and curb ramp

Concrete is by far the most common form of pavement material used for sidewalks in the United States. It is a mixture of cement, water, aggregate, and sand. It is very durable and has a life of between 40 and 80 years. It is poured material and within 15 to 30 minutes a smooth finish is applied to the surface followed by a broom finish to help with traction. Because of its semi-fluid state when it is poured it is an especially attractive material to use when there are multiple grades and cross slopes such at corners and curb ramps. New paving equipment in the past thirty years is now permitting the paving of long stretches of sidewalk without the use of form works. Repair and replacement of sidewalks in concrete is still performed the same way it has 50 years ago with forms and skilled finishers.

Image 2: Asphalt is commonly used for shared use

paths, but sometimes also for sidewalks

Asphalt is less common than concrete and typically has a significantly shorter life than concrete. However, the initial cost for application is significantly less. It consists of a petroleum base (tar) and aggregate. Asphalt must be compacted soon after it is applied to the surface preferably by heavy equipment. This makes it an attractive material for long stretches of sidewalk or path where a roller can be used. Asphalt can be used in other tighter settings, such as corners and curb ramps, where a hand mechanical tamper is used, but results typically do not match that of concrete. Often when asphalt is used for a sidewalk, concrete is used for the curb ramps. Asphalt is commonly used as a temporary patching and wedging material for concrete sidewalks. Asphalt is the common material used for shared use paths in the United States.

Image 3: Brick is often used for sidewalks in

historic areas

Brick is a traditional type sidewalk material used for centuries in the United States. Bricks offer a high level of durability and can be reused and easily replaced. Bricks differ from concrete pavers in that they are made from formed clay which is then fired in a kiln. Bricks and concrete pavers are considered a "segmental material" since each paver is separate and is often not tied or bonded together the way a concrete slab is formed and functions. Proper installation is important for bricks and concrete pavers to reduce future maintenance. Bricks have unique maintenance requirements and many communities consider bricks to be more costly and problematic to maintain than concrete. Some communities are using bricks and concrete pavers to highlight sidewalks in commercial areas or plazas. The main shape of bricks is rectangular and they are manufactured in a wide range of colors. More recently, bricks and pavers have been manufactured and placed to create a more permeable surface, but it requires more spacing between the individual blocks.

Image 4: Concrete pavers are often used in

terrace areas

Concrete pavers are also used for sidewalk applications and for sidewalk border applications. They consist of a mixture of cement, sand and water and function much like bricks when they are set in place as sidewalks or walkways. Like bricks, concrete pavers can be produced in many shapes, sizes and colors. They are durable, versatile and can be reused; however, they do have unique maintenance requirements. Like all other sidewalk materials, attention to proper construction can reduce maintenance problems and costs in the future.

Image 5: Rubberized pavers have seen increased used in the past few years

Pavers made from recycled rubber and plastic have recently been introduced as a substitute for traditional sidewalk pavements. These pavers are modular systems similar to large concrete pavers. They are linked together with tabs. Communities have been attracted to these pavers for applications around trees where tree roots have caused concrete sidewalks to heave, although they can be used in most environments calling for sidewalks in a straight alignment. They are half the depth of concrete sidewalks and are typically more expensive than concrete in most applications.

Research conducted for this report did not identify use of permeable pavements for sidewalks and paths. Discussions with communities did not lead to any discovery of permeable materials; however, since this is an emerging pavement type, it will be covered in the Guide, but not discussed in detail in this research report.

Table 3 compares some of the materials described in this section based on cost, lifespan, maintenance requirements and repair or replacement costs. Because these figures vary widely based on region, climate and specific application, only relative values are used to compare one material to another.

Table 3: Relative comparison of various sidewalk materials

| Material | Cost | Lifespan | Maintenance | Repair or Replacement Cost |

|---|---|---|---|---|

| Concrete | $$ | *** | Low | High |

| Asphalt | $ | ** | Moderate | Moderate |

| Brick | $$$$ | *** | High | Low |

| Rubberized Pavers | $$$$ | Low | High |

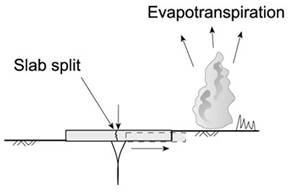

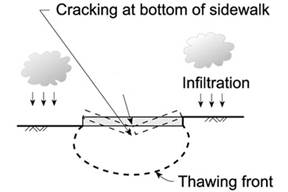

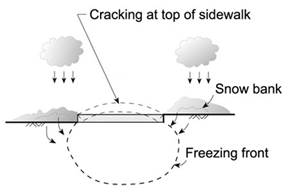

There are a series of structural failures that lead to the vast majority of sidewalk problems and hazards. Many of the forces that cause damage to sidewalks are related to frost action. Note paths that are paved in concrete share the same deformation problems as concrete sidewalks. The Institute for Research in Construction of the Canadian National Research Council has undertaken an extensive study of concrete sidewalk issues and has defined four major deformation types leading to structural damage to sidewalks. An additional type was added and involves surfacing problems that are not structural in character. These five conditions are identified in Table 4. These same conditions cause failures in asphalt, as well as bricks and pavers (sometimes referred to as segmental pavements). These resulting failures will also be highlighted as follows although they were not part of the Canadian research study report.

Table 4: Types of sidewalk deformations as identified by the Canadian National Research Council

The tendency for a concrete sidewalk slab to rise, subside or tilt as a result of expansive native soil, frost action or thermal expansion of the concrete slab. This could also be due to non-uniform compaction of the subgrade. Since asphalt has a high tensile strength compared to concrete, deformation around the uplift will occur often causing a crack or a mounding of the material, but typically not a break characterized by a rift or fault of the material as seen with concrete.

Image courtesy of PVC Pump

Deformation resulting from tensile stresses caused by the shrinkage of underlying soils from decreasing moisture content. As a clay or silty subgrade dries, the strong bond of the subgrade to the underside of the concrete induces tensile stresses in the concrete slab as the subgrade shrinks. The concrete slab will crack when the tensile stress exceeds the tensile strength of the concrete.

Illustration courtesy of Canadian National Research Council

The unequal movement of the slab as a result of the center of the sidewalk or path having a larger thaw settlement than at the edges, or native soil conditions where clays swell significantly at the edges. This leads to longitudinal cracking.

Illustration courtesy of Canadian National Research Council

Unequal movement of the slab caused by frost heave or upward vertical movement due to swelling of clay native soils being greater at the center than at the edges. Raised pavements are also commonly caused by tree roots. Hogging also leads to longitudinal cracking.

Illustration courtesy of Canadian National Research Council

The finish of the concrete is compromised. Unlike the previous conditions which are structural in nature, surfacing defects are due to poor concrete quality and finishing. Improper asphalt compaction or improper mixing of the material can lead to premature surface deformation as well. Rarely do bricks or concrete pavers themselves exhibit surface problems since the quality of material is controlled by a more stable manufacturing process.

Image courtesy of City of Middleton, WI

The structural and surfacing conditions in Table 4 lead to a multitude of problems impacting maintenance, which include longitudinal cracks, transverse cracks, faulting, corner breaks, gaps and changes in grade due to settling and heaving.

Longitudinal cracks occur along the length of the sidewalk, usually in the middle third of the sidewalk, and can extend through several expansion or control joints. Transverse cracks occur across the width of the sidewalk due to non-uniform subgrade compaction, especially where sidewalks are subjected to high vehicle loads such as where driveways cross sidewalks.

Although there can be other surfacing problems associated with asphalt surfaces, the common defects from poor surfacing for sidewalks and paths are associated with raveling and cracking. Raveling is caused by high air voids in the material due to poor compaction or late season paving. Cracking can also lead to series of problems for asphalt surfaces overtime. The ones mostly closely impacting sidewalks and paths are edge, alligator, and longitudinal cracking.

The series of defects associated with concrete include spalling, scaling and popouts. Poor curing practices, concrete quality or finishing techniques can all contribute to these defects. Often these surface defects will appear in the first several years after application. Minor defects may only affect appearance, but moderate to severe conditions will ultimately become a safety concern and significantly affect the usable life of the sidewalk.