U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

This section of the Guide identifies issues that need to be monitored during the placement and compaction operations of the AC pavement.

The paved lane/shoulder width and location of the Safety EdgeSM break point should be

discussed and established prior to paving. The Safety EdgeSM can be constructed on the

unimproved or improved shoulder with the break point lining up directly over the existing

pavement edge or over any portion of the previously paved surface as shown in Figure 9.

Figure 9. Paver positioned to align the Safety EdgeSM break point over the existing pavement.

The intent is not to sacrifice paved lane/shoulder width to construct the Safety EdgeSM. Constructing the Safety EdgeSM onto the unimproved shoulder does not result in a decrease in paved lane/shoulder width.

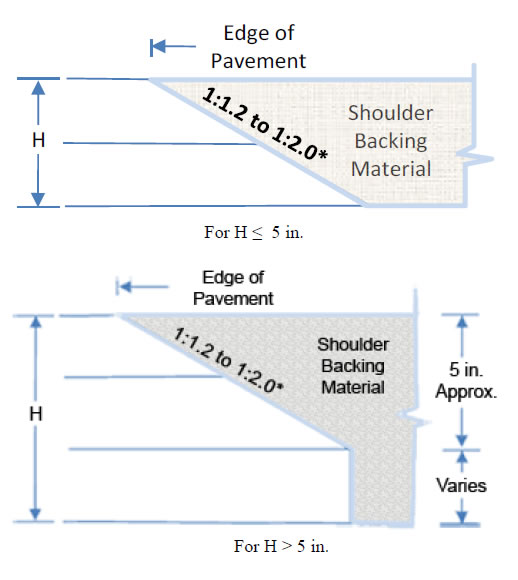

The Safety EdgeSM is designed to create a 30 degree finished angle, relative to the pavement cross slope, on the edge of the pavement. Agency-specific tolerances may vary from those shown in Figure 10 which is from the FHWA guide specification. On projects where multiple AC layers are used, it is recommended each AC layer (except leveling layer) of the final 5 inches of AC receive the Safety EdgeSM as shown in Figure 10. For new construction or reconstruction with thicker AC layers, consideration should be given to widening the underlying paved layers to accommodate the Safety EdgeSM without decreasing lane width as shown in Figure 10. On projets with multiple AC layers, it is expected the additional volume of AC required to form the Safety EdgeSMwill increase bid quantities.

*Note, Recommended Rise to Run ratio range 1:1.2 to 1:2.0. The range of slope is equal to 26° to 40°.

Figure 10. Recommended Safety EdgeSM configuration for AC pavements and overlays.

The current commercial Safety EdgeSM devices can be grouped into two categories: (1) devices attached to the paver screed, and (2) modifications or attachments to the paver end plate. The devices listed below do not constitute an approved products list. Highway agencies should evaluate any new Safety EdgeSM hardware for compliance with specifications before approving for use on a project.

Devices Attached to the Screed

Currently, there are three devices available from two different manufacturers, which are: (1) the “Shoulder Wedge Maker” manufactured by TransTech, www.transtechsys.com and (2) the “Advant-Edger” and “Ramp Champ” manufactured by the Advant-Edge Paving Equipment LLC, www.advantedgepaving.com. Each manufacturer provides detailed installation instructions for attaching their devices to the paver screed. The devices can be easily attached to and removed from the paver screed with a simple two-bolt connection. The Safety EdgeSM device should fit closely to the end plate to prevent AC from getting between the device itself and end plate. The Ramp Champ can be set to a range of angles, while the other devices have a fixed angle.

End Plate Modifying Devices

The end plate modification devices are available from Carlson Paving Products, Inc. (Safety Edge End Gate) http://www.carlsonpavingproducts.com and Willow Designs LLC http://www.willowdesignsllc.com. The ski of the devices form the slope of the Safety EdgeSM and can be set to a range of angles. The screed operator can adjust the angle of the ski while paving to ensure the final angle of the Safety EdgeSM after rolling is close to 30 degrees.

The Safety EdgeSM can be placed with all dense-graded AC materials that have been properly designed in accordance with existing mixture design methods, including: Hot Mix Asphalt (HMA), Warm Mix Asphalt (WMA), HMA with high amounts of Recycled Asphalt Pavement (RAP), HMA with Recycled Asphalt Shingles (RAS), polymer modified asphalt (PMA), rubberized gap graded and open graded mixes, and other specialty mixtures. The demonstration projects included HMA, RAP, RAS, WMA, and PMA mixtures.

There are two critical material issues in terms of placing a Safety EdgeSM for AC mixtures: (1) lateral movement of the AC mix during compaction and (2) the size or amount of coarse aggregate in the AC mixture.

Figure 11. Longitudinal crack due to Safety EdgeSM break point located on unimproved

shoulder.

This section discusses items of interest to asphalt paving projects when a Safety EdgeSM is to be placed as part of the new construction or rehabilitation project.

Safety EdgeSM Device Installation

Manufacturers of commercially available devices provide detailed instructions for attaching the Safety EdgeSM devices to the paver. Proper installation of the devices was discussed in a previous part of this section (Equipment – AC Safety EdgeSM Devices). A key issue for devices attached to the screed without guide rails is to ensure close installation to the end plate so loose mix does not get trapped between the device and end plate during paving operations. At the beginning of the day's production, when pulling off a transverse joint, the screed operator needs to monitor the position of the device as the auger chamber and extension are being charged to ensure the device is in contact with the end plate. These issues do not affect the end gate type device.

AC Placement

The Safety EdgeSM can be placed with normal paving procedures, and no changes to the operation of the paver need to be made. More importantly, the Safety EdgeSM device has no impact on how the paver operates, whether paving on an embankment or crushed stone layer, recently placed AC, existing AC or PCC layers, or milled surface.

For those agencies that require trial or control sections as part of standard AC paving operations, the slope of the Safety EdgeSM should be measured after all rolling has been completed to ensure the Safety EdgeSM slope did not "stand up" (substantial increase in the slope). Trial sections provide an opportunity for the screed operator to make adjustments to the Safety EdgeSM and screed before high production paving begins. For example, to obtain the 30o finished angle, the target angle to be achieved behind the paver by the Safety EdgeSM device may need to be shallower for a given mix, e.g., 25 degree. Trial sections can also be used to assess if the edge will "stand up" during the AC rolling operation. The issue of maintaining the slope of the Safety EdgeSM is discussed under the next subsection – Rolling.

The screed operator needs to watch and adjust three items during the paving operation when using a Safety EdgeSM device attached to the screed, described in Section 3.2: (1) the Safety EdgeSM device itself, (2) the end plate, and (3) the screed (refer to Figure 12). If the Safety EdgeSM device with too much downward pressure rides on the AC or other stiff base material that has been previously placed, this can result in undesirable paving results, as described below.

Figure 12. Safety EdgeSM adjustment for raising and lowering the device.

When paving begins the screed operator should pay close attention to the following items when using a Safety EdgeSM device attached to the screed.

When using a Safety EdgeSM device the screed operator needs to continually be aware of the position of the break point of the Safety EdgeSM slope and keep the break point on the structural base or existing pavement.

At the beginning of the project, it is recommended that slope measurements be made immediately behind the paver and after each roller pass. The focus is on the final Safety EdgeSM slope angle after all rolling to determine how rolling impacts the final slope angle.

The contractor may want to periodically make these measurements as part of the quality control process.

Rolling

No special rollers are required for compacting the AC mix along and adjacent to the Safety EdgeSM (refer to Figure 13).

Figure 13. Rolling the Safety EdgeSM with standard rollers – No special rollers are required.

Most AC mixtures exhibit some lateral movement under the rollers during compaction. Lateral movement of the AC mix should not prevent the contractor from achieving an acceptable Safety EdgeSM slope after final rolling. For some of the demonstration projects, the contractor did change or revise the standard rolling pattern to maximize the density of the AC mat, while retaining an appropriate Safety EdgeSM angle. Just like for any AC paving project, the optimum rolling pattern is AC mixture specific. A rolling pattern used to compact a low stiffness mix and high stiffness mix may be different to meet the density requirements.

The following recommendations are made based on the findings from multiple demonstration projects.

The same properties used or identified by the owner agency to measure the quality of AC pavement layers for acceptance should also be used on projects that include the Safety EdgeSM. The acceptance plan should not be modified for projects that include the Safety EdgeSM. More importantly, the density, strength, and/or smoothness requirements appropriate for a typical project should not be relaxed simply because the Safety EdgeSM is added to a resurfacing or new construction project. Thus, the only difference between projects with and without the Safety EdgeSM is the slope of the edge itself.

| << Previous | Table of Contents | Next >> |