U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

| < Previous | Table of Content | Next > |

This chapter provides an overview of the specific tag identifier technologies, and their relative performance, used by transportation agencies to tag roadside safety hardware. This review focuses on the following three primary tag identifiers as ID methods:

There was no clear separation in the literature or practice between uses of barcodes and serial numbers as tag identifiers (often barcodes have both the printed matrix and serial number). Therefore, they are treated as the same method in this chapter. It is assumed that transportation agencies would deploy both barcode and serial number technologies post-manufacture by creating and attaching a tag using the same printing and installation process.

Barcode tag identifiers consist of printed lines, spaces, and shapes on a tag that users attach to the product or asset they want to track. Similarly, serial numbers are a group of alphanumeric characters that users print on a tag and attach to the product or asset they want to identify and document.

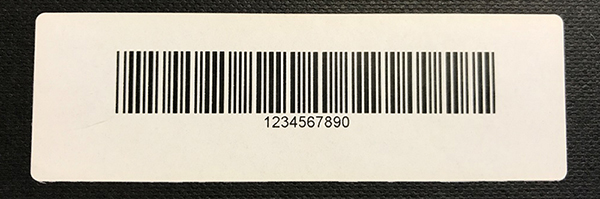

In considering barcodes and serial numbers, the construction of the tag is very similar, and often manufacturers print both barcodes and corresponding serial numbers along with any additional information a buyer might want on the tag (see figure 5). Barcode standards are provided by the GS1 system established by the Uniform Product Code Council, which has been in place since 2005.

Figure 5. Image. Combination barcode and serial number tag.

The barcode ID method uses a system made up of the tag and the scanner/software.

There are two primary types of barcodes: 1D and 2D. The most common type is a 1D barcode, which consists of parallel lines and spaces (see figure 5). The 2D barcodes consist of a combination of dots and geometric shapes or a matrix (see figure 6). More than 44 different barcode formats (various ways to present the lines, spaces, and dots) are commercially available.

Figure 6. Image. 2D data matrix barcode.

Generally, 2D barcodes can hold more information (numeric and alphanumeric) than 1D barcodes. The maximum amount of storage on a 1D tag is 48 alphanumeric characters. The maximum amount of storage on a 2D tag is 4,296 alphanumeric characters.(21, 22)

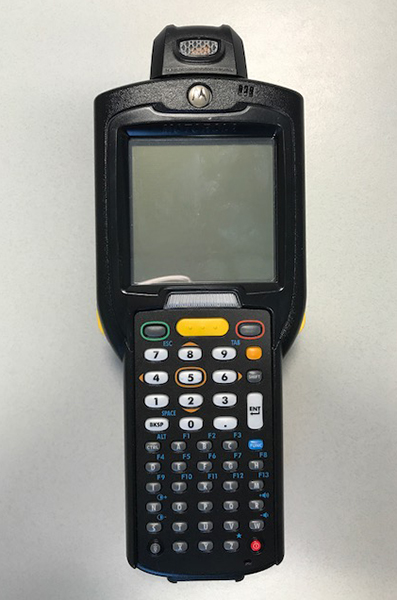

Similarly to RFID, a user must deploy a barcode scanner or device capable of scanning a barcode (a cell phone or tablet, for example) to read the barcode (see figure 7). The scanner decodes visual information and sends it to a user's handheld device or computer, which has software to read and store the information. Most barcode scanners consist of three parts: an illumination system, sensor, and decoder. The scanner uses red light to illuminate the tag, and then a sensor detects the reflected light and generates an analog signal, sending it to the decoder.(23)

Figure 7. Photo. Barcode scanner.

The performance of barcode tags depends greatly on many factors, including:

Users can print barcodes on any printable medium and use a cell phone or tablet to scan barcodes. Tags that can withstand harsh environmental conditions may cost considerably more. Information can be scanned directly into readily available office spreadsheet programs or can require complex software to code specific elements into agency databases. Formal systems with proprietary software can be costly. Therefore, barcode software acquisition costs range from $2,500 to $35,000 despite barcode labels themselves being inexpensive.(12) This cost excludes training, support, server software, and personal digital assistance (PDA) software.

Price is greatly impacted by the quantity, material, and size of tags ordered, along with the attachment mechanism. For example, for a 2-square-inch aluminum tag hardened for exterior conditions having a thickness of 12/1000 of an inch with adhesive, the price is $0.42 each for an order of 10,000 units, while changing the thickness to 20/1000 of an inch raises the unit price to $1.40. These tags have a 30‑year life expectancy in harsh environments. Polypropylene, polyester, or vinyl tags can cost as little as a few cents each but would not stand up to harsh environments.

While the RFID ID method may seem like simply an ID tag, it is a system that includes three basic components—the tag, the reader, and middleware.(25)

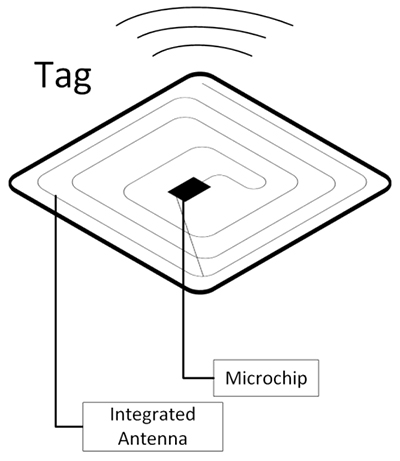

Figure 8 presents the standard design of an RFID tag. It includes two parts: an antenna for receiving and transmitting a signal, and an integrated semiconductor (microchip).

Figure 8. Image. Basic RFID tag.

Types of RFID Tags

There are three types of RFID tags:

The RFID industry has multiple standards and an established class system.(28) The Electronic Product Code standard specifies longevity and memory requirements. Additional information on the standards and classification is included in Appendix A.

No matter the type of RFID tag, they transmit data by three frequencies:

The UHF tags are considered the most practical for unique-item tracking, offering a high reading range, speed, and rate. At practical application distances, UHF is strong enough to penetrate walls and other materials; however, long-range reading of UHF tags (thousands of feet and typically for active tags) requires line of sight similar to television antenna waves so that the signal is not blocked.(25)

Tag Memory

Manufacturers and standards specify that RFID tag memory can be accessed in three ways:

RFID Readers

The RFID reader is a device that scans RFID tags and communicates the results to the bridging software known as middleware. The reader has its own antenna and communicates by broadcasting radio waves, awakening all tags operating in the same radio frequency. Some readers have additional abilities such as anti-collision, encryption and decryption, and transponder-reader authentication.

Readers can be handheld (figure 9), stationary, or mobile.(25)

Figure 9. Photo. Handheld RFID reader.

RFID Middleware

Middleware connects the readers and the data read from a tag to a database or enterprise software and/or information system. The middleware applies filtering, formatting, and logic to captured data. The middleware then provides access and data flow capabilities to/from back-end systems.(25) Middleware is often included within the reader.

The RFID tags have various potential technical limitations, including the reading rate, the reading distance, the impact of tag size, and use on metals and in wet conditions. These limitations are important for transportation agencies to understand so that they can use the correct tags for their purpose. This section discusses these possible limitations.

Line of Sight

The RFID technology generally does not require uninterrupted line of sight, though geological structures such as hills or mountains can obstruct the signal.

Reading Rate

The RFID readers can read multiple tags at the same time, up to 100 tags.(29)

Reading Distance

The RFID readers have limited range for reading and acquiring information from an RFID tag. This range varies with the type of tag. Users can read active RFID tags up to 656 ft. (200 m) away and passive RFID tags up to 82 ft. (25 m) away.(36) There is also emerging technology that allows for tags to be read up to 4 miles away.(30)

Tag Size

The size of RFID tags directly relates to the size of their antennas and their associated read range. The larger the antenna and tag, the farther away a tag can be read.(31)

Use on Metal

A common myth about RFID tags is that agencies cannot use them on metal. Non-improved RFID tags attached to metal objects have a history of problems. The metal reflects energy away from the tags and detunes the antenna. Manufacturers have addressed this concern by designing tags with spacers, often using the metal to reflect a greater amount of energy to the tag and increasing read range. In addition, efforts are underway to develop RFID tags using only the metal objects users attach them to as antennas.(32)

Similarly to use on metal, potential users often think that RFID devices are off limits for water. Submersion of an RFID tag distorts the RFID signal from the antenna as the water absorbs energy. Manufacturers have developed techniques to allow for RFID use underwater. By altering the antenna impedance, users can successfully read the tag.(32)

The cost of an RFID tag (not the system including a reader and software) varies greatly depending on tag type and configuration. Generally, passive RFID tags are less expensive than active RFID tags.(33) Table 1 shows the various price ranges for passive and active RFID tags according to different sources.

| Source | Passive (UHF) | Active |

|---|---|---|

| Atlas RFID(34) | $0.15 to $5.00 | $15 to $100 |

| Impinj(35) | $0.50 to $2.00 | None |

| Bridden(36) | $0.10 to $7.00 | $4 to $30 |

| RFID Journal(37) | $0.20 or more | $10 to $50 |

Tag costs are dependent on many things, including materials and manufacturing process as well as conditions for use (on metal or near water). The shape and application also impact price, and if the tag is a specialty tag, such as an eyelet, or is flexible enough to wrap around an object, the price is slightly higher. Price is directly related to the number of tags ordered; some prices drop almost 30 percent from an order of 100 tags to an order of 25,000 tags. There is also a relationship between durability and tag costs, especially for temperature extremes. A current price list based on quantity and durability is provided in Appendix B.

Maintenance cost should also be considered. The battery life for active tags ranges between 3 and 5 years. Some advancement in battery technology claims a 10-year life for active tags, but there is no easy way to determine when battery life has ended. This factor has implications for the cost of maintenance since transportation agencies will have to replace active RFID tags on a periodic basis. Transportation agencies should consider replacement costs if they choose to deploy active RFID tags.

Handheld readers with middleware pre-installed cost hundreds of dollars, while stationary readers can cost $1,000 or more.(27) Users can purchase UHF readers ranging from $500 to $3,000 depending on their added functionality.(37)

Barcode and RFID systems include the tag identifier, readers or scanners to read the information, and middleware or software to store the information. System performance depends on line of sight, reading rate, reading distance, tag size, use of metal, and use near water. Serial numbers can be read and data entered manually. They can be stamped directly on roadside safety hardware or printed on a tag identifier. Since serial numbers are commonly used in combination with barcodes, they were treated as the same method in this chapter.

Once transportation agencies are familiar with the different tag identifier technologies as ID methods and their performance, the agencies can select the ID method that will work best for them. The next chapter describes several factors that transportation agencies may take into consideration while making this decision.

| < Previous | Table of Content | Next > |